Cable tray installation isn't the most thrilling aspect of any electrical or networking project, but it's one of the most critical. If you do it correctly, they keep your system safe, organized, and easy to service. If you do it incorrectly, you might be facing a tangled mess of wires, burning cables, and costly rework. Super Cable Tray Pvt. Ltd. allows installation of a Cable Trays in an office building, factory, or data center; understanding what to do and what not to do when installing these trays can be time-saving, cost-effective, and effort-minimizing in the long run. Let's analyze the most frequent mistakes made while installing these trays—and how you can prevent them. Whether you’re a contractor, technician, or DIY enthusiast, these tips will help you get it right the first time.

1. Selecting the Wrong Cable Trays Size

This step might sound simple, but it’s surprisingly easy to mess up. Too many people opt for cable trays that are too small for the job. Perhaps they're trying to conserve space, or perhaps they didn't plan for future expansion. Either way, a tray that's too cramped will box in your cables, restrict airflow, and make maintenance miserable. Always measure precisely and plan ahead. Allow at least 25% extra space in the tray for future additions. It's a lot simpler to install a bit of a larger tray now than to replace everything later.

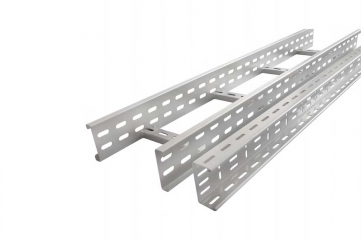

2. Selecting the Wrong Cable Trays Type

Your environment will determine different materials and designs. For instance, ladder cable trays are well-suited for hot zones where airflow is essential, whereas solid-bottom or perforated cable trays will work better in cleaner spaces such as offices or light industrial facilities. Using the wrong type of tray for your space can lead to overheating, corrosion, or just an inefficient setup. Take time to match your tray type to your use case.

3. Poor Support Placement of the Cable Trays

Cable trays should not be suspended unsupported in the air over distances. The most common error that appears all too frequently is installation of supports spaced too far apart, which allows the tray to sag under the weight of cables. Sagging is not only aesthetically undesirable—it also causes stress to the cables and accelerates wear in the long run. Follow manufacturer guidelines for tray support spacing. It generally varies based on the size, type, and load capacity of the tray.

4. Overcrowding the Cable Trays

When it comes to cables, more is not always better—especially when they’re crammed together in a confined space. Overloading these trays reduces ventilation, increases the chance of cable damage, and makes it harder to locate or replace individual wires later. Plan your cable layout and separate different types of cables—like power and data lines—whenever possible. Use dividers if needed, and avoid crossing wires unnecessarily.

Related Blog: Why Are Cable Trays Important in Modern Electrical Infrastructure

5. Ignoring Grounding and Bonding

Metal cable trays, particularly in industrial settings, need to be grounded and bonded to prevent electrical shock and fire. Certain individuals believe mounting the tray onto a metal framework is sufficient, but this may not always be the case. Employ bonding jumpers between tray sections and stick to electrical codes rigorously for safety.

6. Forgetting About Future Expansion

It's simple to think only about immediate needs. But what if you need to add additional cables in the future If your trays are full or difficult to reach, you'll have to upgrade the entire system—an expensive and time-consuming process. Leave some space in your trays, put in accessible trays, and label it all clearly.

7. Cutting Local Codes and Standards

Every nation—and even every city—may have its own electrical codes and regulations. Disregarding these can result in failed inspections, safety hazards, or having to do the whole installation over. Always look up local regulations prior to starting. If you're still not sure, talk to a seasoned electrician or engineer who's familiar with the local regulations inside and out.

8. Poor Fitting and Alignment

Incorrect tray section connections or neglecting the proper fittings for bends and junctions can become stress points for your cables. Misaligned trays also hinder cable pulling and enhance the likelihood of wear and tear. Employ the proper fittings, align them meticulously, and fasten each section securely. It may require a bit more effort, but it is worth it in smoother installation and more durable performance.

Small Details, Big Impact

Installation of cable tray can appear easy, but the most minute errors can cause huge issues. From the selection of an appropriate tray size and type to support grounding and proper spacing, all details contribute to the success of your system overall. By avoiding these pitfalls and planning carefully, you can make sure your cable trays are functional, durable, and safe. Regardless of whether you are dealing with a small office or an intricate industrial system, doing it right the first time saves you in safety, efficiency, and peace of mind.