The demand is coming with an increase for systems which are more organized and safer electrically, which is a strong factor to increase where industries expand and the smart buildings are becoming popular for new structured wiring. The Cable Trays from Super Cable Tray Pvt. Ltd. provide a blueprint for all this; it's an anodized version of the cable tray handles the ungrateful challenge related to the implied bleed in respect of carrying the distribution lines, their grouping, while ensuring their accessibility and safety. These trays, beyond simply handling wires, represent a forward leap in thinking in terms of efficiency, maintenance, and the whole life of the electrical distribution system. Meeting the design pursues cleanliness in routing, reduces the length of installation, and boosts the aesthetics of high-tech indoor spaces-from server rooms to factory plants.

Simplicity To Essential Design Solutions

Cable management is no longer taken for granted as an element of construction planning. In today's era of high-rise structures and other infrastructural developments, the significance of early-stage planning cannot be more heavily appreciated. Cable trays demonstrate this. These hardy structures may take on different shapes to complement any given architecture and are especially apt for industrial and commercial settings. They are wide open, allowing visibility and making inspection, future provisions for more cables, and upgrading easy. Also, they maintain clear correctness and professionalism in organized pathways.

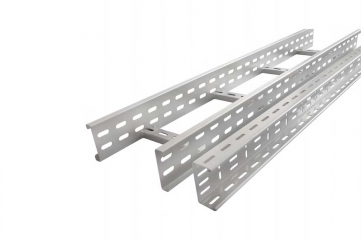

Ladder-Based Systems In Heavy-Load Applications

Few systems can compete with the Ladder Cable Trays for some heavy electrical loading and large runs of cables. These solutions are robust and straightforward in their design. Made to deliver the highest quality and performance, these trays are the most sought-after support for heavy-duty electric cables. An open design helps air circulation to prevent overheating in large systems. Offered in surroundings like manufacturing plants and power plants, ladder-type systems provide an assurance of safety, long life, and permanent performance without compromising performance. Corrosion, impact, and mechanical damage make the system good for extended work life even in hostile environments. Featuring strong construction, it makes any plan to have it withstand external stress, like moisture, dust, grit, or heat.

Safety In Built Form For Every Stage

Safety—this is of utmost significance in any wiring task. Proper installation of all such trays also functions to reduce any mess and cluttered area and help prevent wire damage, thereby avoiding catastrophic fire risks. These trays keep track of cables, provide a faster facility for fault detection, and ease regard of design bias in favor of routine inspections. A disciplined tray system facilitates compliance with safety regulations, thus allowing the entire electrical network a longer lifespan. In essence, rather than heavy traffic from above or staff movement in technical zones, safe cable pathways minimize tripping hazards and equipment downtimes.

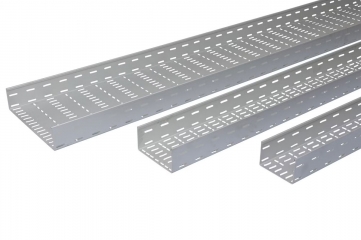

Light Applications Seek Uniquely Designed Structures

Some settings function without the need for heavy-duty structures. For places like offices, hospitals, and commercial buildings, Perforated Cable Trays offer the best from a practical and aesthetic perspective. Holes down to their patterned design make it easier to manage the handling of small cables, promote airflow, and minimize the buildup of dust and moisture. Their compact profile makes them ideal where accessibility and organization are of utmost importance. Their flexibility allows routing adjustments to negotiate angular bends or tight corners, while still providing stability.

By now, it is quite obvious that cable trays have become the heart and soul of power management in today's age. From the tower manifestation of a ladder system to simply necessary efficiency of a perforated system, they duly cater to a mammoth range of electrical needs. Simplicity is thus in place with these silent design-efficacious components of tomorrow. These trays are used in a wide variety of methods, from smooth buildings to industrial zones, hold the future challenge therein, literally and execute with sheer machine-like precision. In blending with infrastructures that greatly fluctuate, cable systems show themselves to be highly adaptable, reliable and cost-effective in any smart cabling planning.