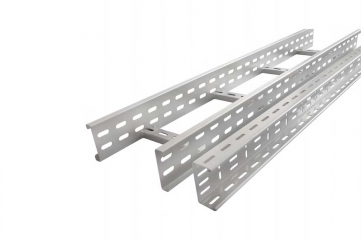

The decision you make for a suitable installation cable management system can be important for all industrial, commercial, and large-scale residential projects. The efficiency, safety, and longevity of your electrical infrastructure really depend on the decision you make at this stage. A well-designed system ensures that cables are arranged within your facilities, protected, and easy to access when maintenance is required, saving time and money while helping prevent hazards in the long term. For that reason, Super Cable Tray Pvt. Ltd introduces Galvanized Cable Trays, which are up to the stringent quality standards for the construction of reliable ones against corrosion for businesses. Now, before choosing, here are some important considerations that could help in having the right solution.

Material Quality Matters

A cable system would perform optimally as intended if, in fact, it lasted long. These types of trays are made from steel that resists corrosion, thereby ensuring durability even in the most critical indoor, industrial, or high-humidity environments. High-quality galvanized trays are very capable of withstanding moisture, chemical exposure, and physical wear and tear. This is important for installations where products are going to be subjected to environmental stress both indoors and outdoors. Promising to invest in reliable products reduces their frequent replacement, which could guarantee a stable long-term infrastructure. Some Key Features:

- Rust and corrosion resistant.

- Strong and sturdy construction.

- Lasts long performance.

Load-Bearing and Structural Support

Cable support systems were designed to carry the weight of multiple cables without any sagging or bending in the system. Improperly designed systems cause damage to cables, operability issues, and increased maintenance expenses. Proper structural support ensures safety for the tray as well as for the cables it supports. Good cable trays can restrict either one or two kinds of damage to cables by avoiding overloading, permitting inspectors and maintenance men to discover potential design problems early and go directly to their effective resolution. This is even more so in industries where production entails a myriad of cables carrying very high electrical loads. Some of the Major Benefits:

- Balance weights.

- Compatible with dense layouts of cabling.

- Fortified for heavy-duty usage.

Heat dissipation and ventilation

Overheating is one common problem with cable installations, which considerably shortens the life of the cable. Open-topped tray designs ensure free airflow around the cables, which keeps them cooler and their insulation protected. A well-built Cable Tray helps ease the pressure on cables and protects them from damage caused by excess load. It minimizes fire hazards, reduces the loss of energy, and allows for contributing to a safer, efficient electrical system. Notable advantages:

- Open structure promotes ventilation.

- Prevents overheating of cables.

- Maintains optimal electrical efficiency.

Installation and Adaptability

One also gets the ease of installation, the best feature of these trays. They have been built for easy fitting, along with the best types of usage in a strong-built system for hassle-free opening of the project. The modular designs allow you to make modifications to future expansions or layout changes, all with minimal effort. We offer quick installation while assuring durability. Core Benefits:

- Quick and easy to install.

- Easily increased or rearranged layout.

- Convenience during inspections and maintenance.

Choosing the Right Tray Type

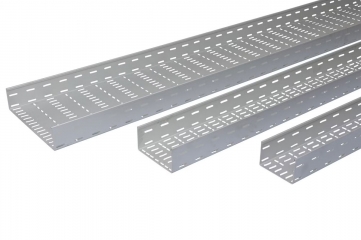

Not all tray suits all applications. For instance, a Gi Perforated Cable Tray is ideal in situations where enhanced ventilation or reduced weight is required without compromising structural integrity. We offer excellent tray designs that deliver practical functionality and long-lasting performance. Here are some highlights:

- Lightweight yet durable design.

- Greater airflow through perforations.

- Fits well into tight or complex spaces.

Compatibility and Integration

A cable tray system should sit as part of a fully compatible infrastructure. That makes the installation easier but also ensures that you meet your requirements for future expansion. Integration improves system functionality regarding safety and operability. A well-integrated system keeps cables from tangling, facilitating maintenance and providing a neat, organized setup, supporting the current and future electricity needs of the company. Key Points:

- Suits all types and sizes of cables.

- Works smoothly with current supports and conduits.

- Maintains clean and organized routing for power and data cables.

Long Term Cost Efficiency

Ultimately, a good galvanized cable management solution will translate into savings in the long run. The initial cost may be higher than with some other options, but the reduced maintenance, plus the longer lifespan and safer usage, will add a considerable amount to the total savings. Long-term efficient businesses derive both durability and compliance from galvanized trays, thus ensuring an extension of the portfolio as the organization grows. Important Benefits:

- Fewer replacements required.

- Reduced downtime from maintenance.

- Lower risk of electrical damage.

Making Smart Choices

The proper choice of cable management system affects operational efficiency and long term safety. Making a decision can be simplified by weighing materials of good quality, load-bearing capacity, ability for ventilation, flexibility in installation, the type of tray required, compatibility, and long-term costs. Good solutions promise durability, reliability and less complicated maintenance, supporting projects effectively across the years.