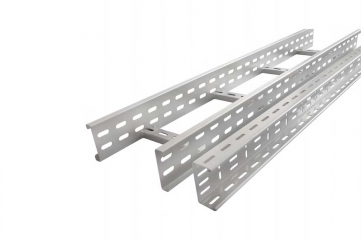

An effective cable management system is important for the safety and efficiency of an electrical infrastructure. Whether it is an industrial unit, commercial complex, or large residential project, properly managed cable systems reduce hazards and ensure smooth operation. Of all the available solutions, Galvanized Cable Trays are well known for durability, resistance to corrosion, and convenient and uncomplicated installation. The material selection for different trays determines how well your system will excel over the long run.

Material Strength & Durability

It is mainly the material from which your cable tray system is constructed that ultimately defines its strength. These trays are made of steel with a layer of coating of zinc, which gives them the ability to withstand moisture, chemical action, and physical wear. Thus, these trays are advisable to be used in the harshest environments where long-lasting strength and durability are called for. Key advantages:

- Rust and moisture protection.

- Longer service lifespan.

- Endures tough environments.

Choosing the Right Tray Design

Each installation is different, and the trays will be designed to suit the requirements of the installation. Some trays provide better ventilation, whilst others are for heavier applications. Investing the time in fleet trays that best suit your project requirements will guarantee they will be effective and will work every time. Some other considerations:

- Open forms for airflow or closed.

- Support structure compatibility.

- Heavy cable support.

Load-Bearing Capacity

Picking trays based on how much weight they can handle while minimizing the chance of any cable damage due to bending or sagging of trays is fundamental. In a properly designed system, the weight is evenly distributed, rendering a steady and working infrastructure. Look for:

- Strong reinforced sections.

- Even load distribution across the system.

- Support for dense cable bundles.

Ventilation/Heat Management

Cables produce heat when conducting power, and when not ventilated, this heat can result in reduced cable life span or other serious issues. Trays that embrace natural airflow through open designs avoid bypassing overheating and therefore put the systems away from danger. Why this matters:

- Prevention of overheating.

- Protection of cable insulation.

- Accord reduction of fire risks.

Installation Flexibility

Changes occur during projects, and having a system that can accommodate such changes makes a difference. Modular galvanized trays allow unilateral assembly for cost-effective installation while permitting future spatial alterations, representing another financially prudent step for industries requiring ways of modifications. Thus, operational flexibilities constitute further adherence in favor of an investment. A few practical benefits:

- Quick and simple installation.

- Easy modifications in layout.

- Convenient inspections and maintenance.

Recognizing Local Demand

The increasing market for Galvanized Cable Trays in India thus reflects the demands of the rapidly growing industries. Commercial high-rise buildings, power distribution systems, data centers and infrastructure projects rely on durable and robust cable management systems. Galvanized metal trays are the kingpin of cost vs performance and continue to be the most popular choice across so many applications. Areas of growing demand:

- Industrial plants and factories.

- High-rise commercial complexes.

- Infrastructure and utility projects.

Role of Manufacturers

Standing behind every good tray system put together is a manufacturer whose competence does not come into question. Choosing a good manufacturer of such trays means benefitting from products whose safety conditions have been adhered to, while the performance has also been top-notch. Worthy manufacturers can also assist with consultation for installations and maintenance, which eases the way for having successful projects. Why reliable manufacturers matter:

- Adherence to safety standards.

- Expertise in design solutions.

- Consistent product quality.

Cost Efficiency Over Time

At first glance, galvanized trays may not seem to represent value for money as compared to others from an initial investment viewpoint; however, over the span of their service life, they offer very high returns on such an investment. Reduced downtime, lower costs from replacements, and lesser chances of damaging cable come together to ensure immense savings in one way or the other. Key savings factors:

- Reduced maintenance costs.

- Extended system lifespan.

- Less operational risk.

Making the Right Decision

Some Galvanized Cable Trays Manufacturers like Super Cable Tray Pvt. Ltd. offer trays that combine strong construction with adaptable designs, thereby gaining the trust of numerous industries ranging from power plants to commercial infrastructure. By considering factors such as material durability, load capacity, ventilation, flexibility, local demand, and manufacturer reliability, businesses can make informed choices that will protect both their investments and their operations.

Building a Reliable Future

Choosing the right tray system is more than just about immediate needs; it is a commitment to a sustainable, safe, and efficient electrical infrastructure. Once wisely chosen, high-quality galvanized trays go beyond protecting cables to fostering the general performance of projects, ensuring easy operations and peace of mind for years to come.