Today, cable management is a crucially important aspect in maintaining the longevity and safety of installations amidst construction and electrical engineering. Whether it is a manufacturing plant, a commercial block, or an infrastructure project, cable organization is paramount for performance and protection. Among the most relied upon and widely recognized solutions for structured cable support are the Ladder Cable Trays from Super Cable Tray Pvt. Ltd.. Having an open design, cable trays are considered within various industries to be the backbone of safe cable management due to their high strength and ease of access.

A Smart Architectural Formation of Cable Tray System

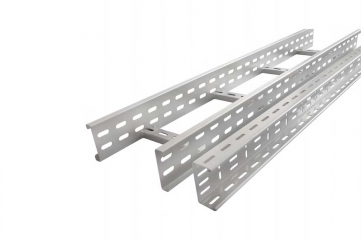

Cable trays are constructed employing two side rails connected by rungs akin to a ladder, hence the name. It is this open rung design that makes this tray uniquely advantageous. It encourages natural air circulation, thereby assisting in preventing the overheating of power or communication cables. Overheating can create serious hazards of damaging insulation or even fire if well above energy levels exist. On the contrary, the open design of these trays helps curb such hazards by providing all around airflow and temperature balancing. Lastly, since the layout is an open one, it is easier to inspect, maintain, or alter cables than an enclosed system, thus saving significant downtime and labor during upgrades or troubleshooting.

Comparing Ladder Cable Tray with Raceway Cable Tray Systems

In the market, several cable management systems are available, but especially when compared with enclosed cable trays, the ladder cable tray stands out. Raceway trays are enclosed ducts often employed in those environments where defense from dust and a good look with some concealment are a must. These are ducted for use in office buildings or indoors, where any exposed conduits and wiring may be considered an eyesore. However, in very large electrical type projects or heavy power load areas, the Raceway Cable Tray very often falls behind in ventilation and access. The heat gets trapped inside the enclosed system, and then one has to spend so much time trying to mash through isolated cables of interest for maintenance. These trays, however, make every cable visible and accessible right at the installation site, thus being the much more practical and safe option to go for in demanding installations.

Planning Installation for Safety and Efficiency

Cable trays need proper installation planning to deliver maximum performance and ensure compliance with safety standards. Unlike their compact brethren, ladder trays typically cover wide distances and might have to hold considerable cable loads. Therefore, they must be installed firmly and supported well between their anchoring points to guard against sagging or structural stresses. When setting up a cable tray system, an engineer must concern himself with cable types, cable amounts, and the very layout of the premises especially future expansions. We must utilize appropriate bends, risers, and junctions to maintain and allow possible changes in cable routings and directions, or elevations. When well installed, these trays can comfortably hold large quantities of power and data cables while being accessible when any modification is required.

Power for Durability: Why Cable Trays Matter

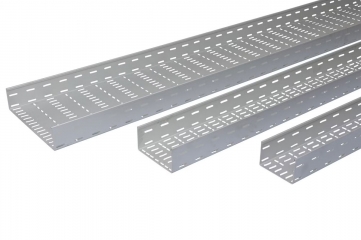

The material constitution of the cable trays is another element that gives the trays their effectiveness and versatility. Usually, aluminum, stainless steel, or mild steel would be used, depending on where the trays are to be installed. And in particular, Galvanized Cable Trays are more and more being used in outdoor or industrial environments. Galvanizing is the process of coating the steel with zinc, which acts as a great protective layer against corrosion, rust, or exposure to chemicals. Durability arising from this coating makes the galvanized trays perfect for hostile environments like chemical plants, coastal installations, or humid areas, wherein unprotected metal will deteriorate rapidly. Their longer life, coupled with reduced maintenance, renders them a very economical option over time.

Ladder trays are not simply for bringing structural support to wires, but constitute a strategic investment in safety and efficiency, which leads to ease of adaptability. These go into the big cable management systems due to their heavy duty design, excellent ventilation, and easy installation. While raceway trays might have applicability in very limited or aesthetic focused contexts, ladder trays are always retrieved in a high performance, high volume installation environment. The option of a galvanized tray also boosts its value in that it assures longevity even when facing very harsh conditions. By selecting ladder cable trays for any industrial or commercial project, one will be choosing safety, reliability, and smart planning concerning their infrastructure.