Fast cabling management is the basis of a modern infrastructure in the new age. As construction projects evolve in support of smarter buildings, sustainable solutions, and automation driven systems, the need for reliable, scalable, and safe cable management infrastructure increases multifold. From multi storied commercial buildings and hospitals to advanced manufacturing units and software parks, the foundation of every demanding environment relies upon whether cables are routed, protected, and accessed well. An unsystematic cabling layout may lead not only to clutter and unsafe working conditions but may also invite problems like overheating, signal loss, and increased maintenance. That is where the Perforated Cable Trays from Super Cable Tray Pvt. Ltd. hold importance, as they bring a structured yet ventilated and sturdy solution to cable routing, helping operational efficiency in the long run. A good cable tray system achieves a clean layout, easy maintenance access, fewer system failures, meets compliance, and possesses a modern look.

Heat and Air Circulation

Good ventilation has aided, hence increasing the popularity of perforated trays in present day construction. The trays are finished with holes at regular intervals to facilitate air circulation around the cables. Such trays are required in places where cables are in some way heat sensitive or heat may be generated at high current operation levels. Letting the air flow through them and avoiding overheating will increase the life of the cables and, conversely, reduce damage to their insulation. Such a safety orientation becomes extremely important in buildings with dense wiring networks, like server rooms or manufacturing plants. Overheating causes a lot of damage or even can be a hazard for fire, and herein the perforated trays weigh in as having an extra edge with heat free to escape along their perforations.

Why Cable Trays Become Very Important for Modern Systems of Design

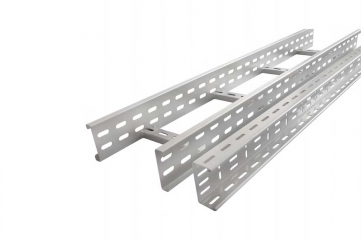

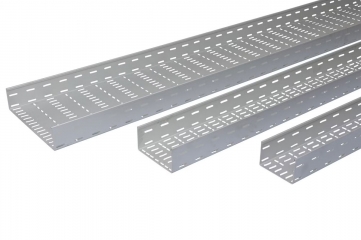

When speaking about cable management, the term Cable Tray embraces countless types of trays depending upon their attributes. Perforated trays fall under this category, but still, they stand a chance to keep power and signal cables intact while presenting them in a neat, orderly manner. Nagging issues arising from digital transformation insinuating automation and connectivity on an industrial level, so that routing becomes too neat to allow any compromise on the placement of data and electrical lines. Perforated types are highly favored in smart buildings, green buildings, and complicated commercial setups where good aesthetics and safety should be equal on the scale. They allow installation on ceilings, underfloors, or walls and thus make it easy for designers and engineers to maintain a very neat wiring system. This maintenanceability again is quite a good reason for the architects to prefer the Cable Trays in modern infrastructure designs.

Load Bearing Strength and Material Versatility

From the point of view of efficiency, perforated trays stand strong and durable. In other words, they are fabricated from a multitude of materials like stainless steel, aluminum, and mild steel, offering a high load capacity without sacrificing flexibility. The galvanized iron perforated trays are ideally suited for heavy applications. The galvanization processes, being a form of coating, protect the tray from corrosion; therefore, the product can be used inside harsh industrial environments or outdoor applications. These Gi Perforated Cable Trays are also mostly preferred in coastal or chemical plant installations where high humidity or chemical exposure would degrade almost any other material over time. Their sturdy construction, combined with corrosion resistance, has made them a long term worthy investment for infrastructure projects that require high resilience and reliability.

The demand for smarter, safer, and more sustainable infrastructure is something that influences the entire design and construction process up to cable management. The perforated trays fulfill this demand with high performance features, adaptability, and lasting durability. These trays, to improve airflow, decrease cable clutter, or endure harsh industrial conditions. With urban construction trending higher, perforated trays will further take precedence as systems get complicated with really elevated height levels. The major cable management phase from green buildings to data connectivity resumes cannot be overlooked at all. For any contractor looking forward to the future, these trays are a wise, thoughtful consideration along the path of electrical systems.