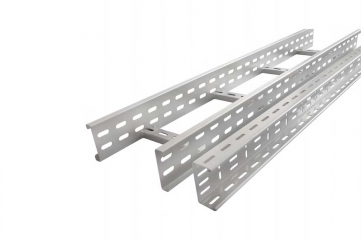

As industries scale, the need for structured pathways to handle electrical and data wiring becomes more critical. Engineers and facility managers lean towards durable and adaptable systems that simplify installation and upkeep. The use of Ladder Cable Trays in infrastructure projects has increased due to its blend of simplicity and strength. One of the biggest advantages lies in its open design, which allows visual access and easy identification of wiring routes without disrupting ongoing operations.

Designed for Flexibility and Growth

A key reason these systems remain popular is the modular nature of their construction. Each section can be added, extended, or reconfigured when new cables are introduced or layouts change. The open rungs allow maximum heat dissipation and prevent cable congestion in high-load environments. Installers can route multiple types of wiring through segmented channels without affecting load-bearing strength or accessibility. Expansion doesn't demand demolition or major rework, making it ideal for organizations that anticipate upgrades over time.

Maintenance Without Operational Disruptions

The open layout enables technicians to spot wear and rectify issues swiftly. Dust accumulation is minimal compared to closed systems, so scheduled cleaning is fast and requires fewer resources. The reduction in hidden wiring means fewer chances of overheating, loose connections, or accidental damage. Unlike enclosed paths, airflow is natural and unrestricted, supporting better performance of sensitive electrical lines. Maintenance teams can isolate and manage individual cable runs without pausing operations in critical sectors such as manufacturing units, substations or data facilities.

Structural Strength and Material Benefits

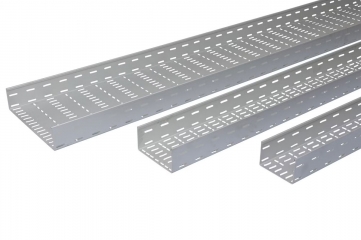

Usually, these types of systems are constructed from steel, aluminum, or some alloys that are corrosion-resistant. The chosen materials are what guarantee that the systems are able to carry heavy weights and resist the conditions of warehouses, factories, or installations outdoors. Besides, the separated rungs not only provide the air passage but also exclude the possibility of the heat being caught. Lengths, widths, and rung spacing can be determined by the designers based on the load, latency needs, and cable thickness. The result is a durable system that can maintain its shape and function without the need of frequent reinforcement.

Seamless Integration Across Industries

From commercial buildings to petrochemical sites, the universal compatibility of ladder-based systems allows smooth implementation. Brackets, bends, and support accessories can be attached securely to walls, ceilings, or vertical frames. Contractors appreciate the speed with which these solutions can be mounted and aligned with existing wiring schemes. Even retrofitting is straightforward, with minimal disruption to equipment or personnel. Integration with fire safety mechanisms and ventilation systems further enhances their practicality across sectors.

Pairing with Complementary Systems

In some situations, closed or semi-enclosed versions are needed by the surroundings for visual or safety reasons. A mix of open and covered routing can thus be used as a balanced solution. Certain use of Cable Tray can maintain a uniform arrangement while allowing the flow to continue without any interruptions. Equipment may have the ability to use these connection or change points for both the vertical and the horizontal runs of the efficient manner. Such a combination is especially valuable in the range of commercial buildings, healthcare establishments, and innovation centers.

Company-Linked Application Example

Distributors and producers of structured wiring solutions supply products that meet customers’ individual requirements through the use of standard models and components that can be customized. One of the features that most industries with stringent compliance requirements is the possibility of having the same equipment in different finishes. Super Cable Tray Pvt Ltd offers specially designed assemblies that match building plans and can also facilitate the installation of a Raceway Cable Tray at any location with enclosed sections for the protection of the area against the intrusion of wires.

Safety, Compliance, and Load Management

Conformity to regulatory requirements is essential when installing large cable routes in industrial spaces. These systems meet stringent fire safety standards, support labeling protocols, and allow space for future equipment additions. The open structure ensures that routine inspections are simple and downtime is minimized. When load requirements change, segments can be extended without replacing entire lines. This adaptability reduces costs and guarantees compliance with updated codes during renovation projects.

Cost-Effectiveness and Long-Term Value

Initial setup is economical as the design reduces the use of heavy enclosures and specially-made supports. The labor time is greatly decreased and, a large part, the installers can work efficiently. The savings, over a period of time, continue to multiply as the system requires low maintenance and allows for easy expansion. Moreover, it is also more convenient to find the replacement parts and install them because of the standardized lengths and the availability of the fittings. This method is considered a trustworthy and long-term solution by organizations that are mindful of their budgets.

Conclusion: Built for Today and Tomorrow

Scaling up the need for wiring in an efficient and manageable manner, the demand for ladder-based systems has risen drastically. Because they can add new wires, carry large weights, and give access without any obstruction, they are being considered a sustainable base of infrastructure in different types of industries. Companies concentrating on safety, productivity, and future planning are getting advantages from such systems that take minimum input but give maximum output. With the development of technology and the expansion of facilities, these trays are still the engineers’ and planners’ trusty helpers who make wiring networks structured and growth-friendly.