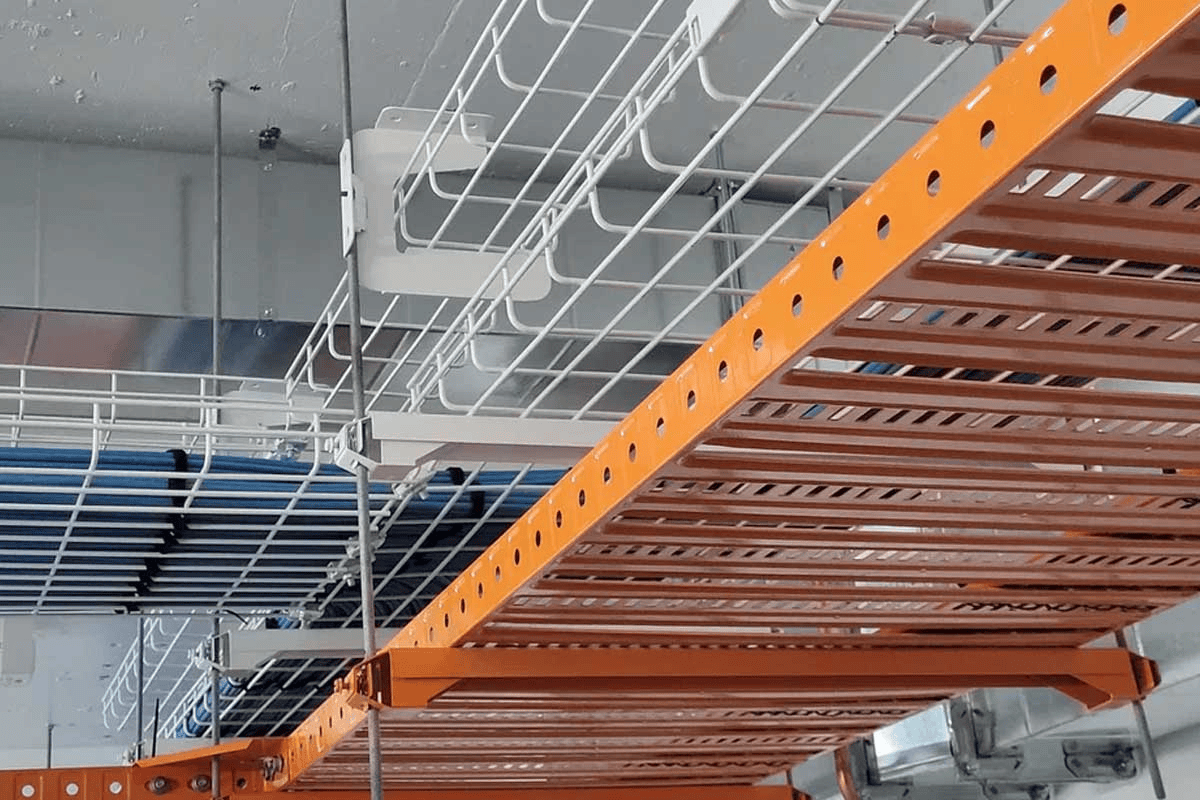

Today, engineering projects are continuing to get more sophisticated than they used to be, and the infrastructure behind such works will surely have to change with this great technology. Installation of electrical setups is now running from wall to ceiling and even under floors, and engineers find ways to install these neatly so they will appear clean, accessible, and less complex. This is the point where the Raceway Cable Tray is beneficial. It acts as an essential support to all wires, wherein they are well contained and routed to safety in the most demanding of environments. Simple and effective, it is also a very good choice for an installation that wants to achieve clarity and performance.

Aesthetic Cleanliness And Long-Term Storage

Cable trays offer some of the greatest advantages over aesthetic finishes in such visible environments as offices, showrooms, labs and tech. These trays fully hide cables and create a smooth and polished look. While the appearance counts, the closed structure prevents an accumulation of dust, little exposure of the cables, and, therefore, potential damage. Engineers love how these systems organize a complex maze of cabling, especially in tight spaces, or when the bunch gets overwhelming. Its ease of installation and maintenance qualify it as a smart investment in any setup for the long haul.

Durable Designs Pairing With Smart Infrastructure

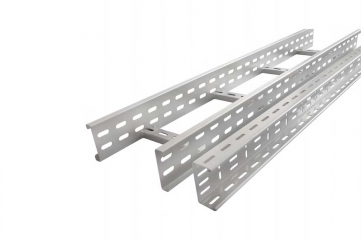

In megasystems where ventilation requirements and separation of cables are primary, Ladder Cable Trays from Super Cable Tray Pvt. Ltd. usually accompany raceways to support equipment with heavier loads or also sensitive to heat damage. Ladder trays normally allow air flow and are typically reserved for high-current applications, while raceways offer an enclosed path to protect these larger systems by routing control or communication lines close by. This open-and-enclosed dynamic is the reason engineers typically employ both in making a balanced infrastructure.

Efficient Modernization And Easy Access

Cable trays aren't only about initial organization-they are meant to change. What is inevitable in every growing or changing system is that an upgrade must be made or new cables added. Because of removable covers, these systems allow very unobtrusive upgrades since they give instant access to internal wiring. This is very important to engineers in places like data centers, hospitals, and commercial spaces; downtime costs and ongoing updates are a fact of life. Minimal disruption and costs much lower than standard rates are the advantages generated with modular designs for rewiring or rerouting.

Safety And Compliance At Every Little Detail

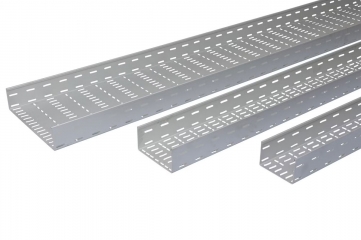

For instance, in environments where safety becomes non-negotiable, cable trays provide a well-controlled protection against external interferences along with accidental wire damage. This kind of enclosed path keeps wires surrounded by moisture and dust as well as subjected to mechanical stresses, reducing the chances of generating fire hazards or short circuits. This much importance is given in certain sectors such as pharmaceuticals, healthcare, and defense. Likewise, raceways are coupled with Gi Perforated Cable Trays in spaces to isolate sensitive or low-voltage wires while power cables remain in the ventilated perforated systems. Thus, these solutions together ensure installations comply with safety regulations while operating at optimal performance.

Building the Backbone of Future-Ready Systems

Automation and the adoption of AI devices and centralized control systems in modern buildings increase the demand for better electrical wiring infrastructures to support the very complicated wiring systems. Raceways introduce the real strength backbone of such future-ready systems. Their sleek, neat routing options keep signal integrity intact while leaving room for expanding networks as required to cope with changing demands. Engineers see them at the hearts of future smart cities, intelligent homes, and tech-integrated offices that lay the foundation for adaptable living. By providing scalability without clutter, these cable trays prove invaluable for use in projects developed to grow and evolve with time.