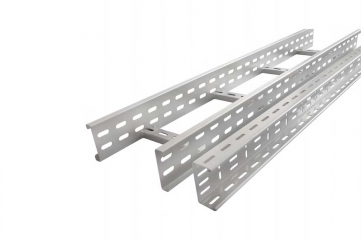

Keeping electrical systems safe and organized depends heavily on the upkeep of cable support structures. The use of a Cable Tray system plays a vital role in preventing tangled wires, fire hazards, and cable damage over time. Whether installed in industrial plants, commercial premises, or residential buildings, maintaining these systems ensures long-lasting performance and reduced downtime.

Schedule Routine Inspections

The first step that you should take is to perform regular inspections in order to find the first signs of damage. Search for corrosion, dents, parts that may be loose, the accumulation of debris or areas that are sinking. By conducting frequent checks you will be able to solve small problems with the risk of them becoming expensive repairs. Also, it is highly recommended to thoroughly examine the horizontal and vertical parts of your tray network for any changes in cable position.

Clean the Tray Surfaces

Dust, moisture, and industrial residue can have a negative impact on the strength and performance of the tray. And, it could be removed using soft brushes or air blowers, without interfering with the cables. The use of strong chemicals that might cause the metal parts to corrode should be avoided. The act of cleaning also makes it easier to see during the inspections and keeps the area around the cables safe and well-ventilated.

Monitor Load Capacity

Overloading a tray can cause a series of issues such as sagging, breakage, and overheating of the wires. Always adhere to the manufacturer's weight capacity recommendations. If your system grows over time, think about cabling redistribution or the setting up of more support structures. Proper load management significantly contributes to the lengthening of installation life.

Ensure Proper Ventilation

Particularly in perforated and ladder trays, avoid grouping excess cables in confined areas. Power and data lines that produce heat during their functioning are usually routed through the Top Cable Tray. One of the heat management techniques is proper spacing which also facilitates heat dissipation. Good air circulation not only cools the insulation but also reduces fire hazards.

Repair and Replace Damaged Sections

Do not postpone fixing trays that show signs of corrosion or structural damage. Replace broken supports, bent covers and rusted joints immediately. If using galvanized or aluminum trays, verify that anti-corrosion coatings remain intact. Keeping spare parts ready speeds up maintenance and avoids interruptions.

Secure Fasteners and Accessories

Inspect that the bolts, clamps, bends, tees and reducers remain securely fixed. Parts that are not properly fitted can cause displacement and put more pressure onto the wires. The equipment vibrations in the vicinity can cause small gaps between the connections; hence, the process of tightening should always be present in your maintenance schedule.

Manage Cable Organization

Proper routing gets rid of the incidents of overlapping and tangled cables. Use ties or separators that match the type of tray to ensure that the cables are in their proper positions. Bending cables to a radii less than the specified one is a performance alteration that might also cause insulation breakdown. Besides that, good organization is an element that facilitates the rapid diagnosing of the fault and the effective upgrading of the system.

Protect Against Environmental Factors

Humidity, chemical exposure, and temperature fluctuations can reduce the durability of metal trays. Consider using protective coatings or covers in harsh environments. For outdoor setups, make sure water drainage is unobstructed and check for any signs of corrosion after heavy rains.

Train Maintenance Personnel

Skilled workers are the backbone of effective maintenance, when they have good knowledge of different types of trays, the installation standards and the safety rules. They get training in tool usage, defect detection and quick issue reporting. This guarantees uniform maintenance methods throughout all locations.

Document Maintenance Activities

Maintain a log of inspections, repairs, and replacements. Documentation helps to track patterns, plan upgrades and assess long-term performance. It also assists in budgeting and compliance with safety regulations.

Use Quality Products and Accessories

Essentially, a maintenance program that is very efficient will not be enough to save the tray system if it lacks durability. The use of high-quality metals and the accessories that are compatible with them is one of the ways you can have strength, stability, and the ability to carry heavy loads. A lot of experts, when they are looking for the durability of the tray over a long period, count on the Super Cable Tray Pvt. Ltd. as one of the leaders in the Best Cable Tray solutions due to their technological accuracy and the usability of their designs.

Plan for Future Expansion

When systems increase in size, the installation of cables is sometimes done without examining the tray's capacity or arrangement again. Design your tray layout considering future expansion. Make room for easy access and extra space to accommodate the new cables without disrupting the current ones.

Conclusion

How to maintain the cable support system effectively will prolong the time that the systems are functional, keep their safety as well as minimize the occurrence of operational disruptions. These all basic through scheduled maintenance will keep both the cables and the installation they serve in good condition. By doing routine work and following proper procedures, one can be sure that the tray system will continue to operate at its optimum capacity and will be able to accommodate future power requirements.