Safety, reliability, and easy maintenance of a modern electrical system would thus be in cable management efficiency. Structured wiring does avoid hazards and achieves superior performance on average. The designing of good Cable Trays assists the structuring of electric wiring, safeguarded against other possible detrimental elements in its surrounding environment. There is no better place than industrial plants, commercial buildings, or a data center to use long-term efficient, durable well-designed parts.

Structural Integrity and Load Bearing Capability

One of the most significant factors for a well-functioning electrical setup is structural integrity. Low-quality support systems will eventually sag, bend, or corrode over time, thereby degrading cable organization and stability. High-quality materials such as stainless steel or aluminum offer excellent strength and are more than capable of handling extreme loads of cables without deformation. A well-designed system maintains its shape under heavy wiring, ensuring that there is no mechanical stress on electrical cables.

Safety and Fire Resistance Improved

The greatest concerns associated with any wiring installation are electrical fires and short circuits. Inferior trays are likely to get overheated and burn the insulation. Solutions with a premium grade of material use fire-resistant material and, thus can have proper dissipation of heat with low chance of a breakout. Really great high-quality solutions can bring improved safety standards while maintaining business regulations over electrical needs.

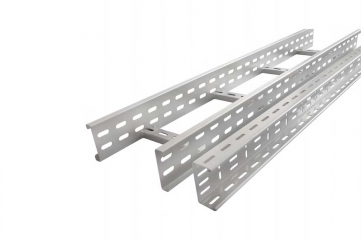

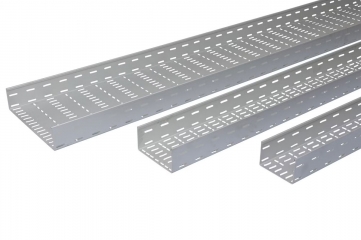

Optimizing Airflow and Heat Dissipation

Heat accumulation in electrical wiring may lead to the breakdown of insulation, voltage drops, and complete system failure. Proper dissipation of heat is important for performance, especially in high-power applications. These Perforated Cable Trays from Super Cable Tray Pvt. Ltd. offers increased ventilation, and thereby, allow excessive heat to naturally escape. Thermal stress on cables is thus decreased, increasing the lifespan of cables and energy efficiency in general. This helps keep the electrical network stable and dependable by preventing high temperature rise.

Simplification of Maintenance and Troubleshooting

Easy maintenance for smooth operations are essential since it is difficult to trace the problems when cables are not arranged or messy, and it takes time. But in a well-arranged setup, it becomes easy to access and inspect the wiring by technicians. Modular in design, high-quality systems usually are easy to change or upgrade as system requirements change. It reduces downtime, lowers labor costs, and makes troubleshooting much more efficient.

Providing Superior Protection Against Environmental Factors

Outdoor and industrial settings expose electrical installations to harsh conditions such as extreme temperatures, humidity, dust, and chemicals. Materials that are of low quality may degrade easily; this would mean frequent repairs or replacement. Once adequate quality components are purchased, long-term protection from these elements is guaranteed. The Raceway Cable Tray, for example, can become an enclosed shielding of cables against contamination or physical damage.

Aesthetic and Space Optimization

Aesthetic appeal is highly valued in commercial environments and data centers. Poorly managed wiring is not only unsightly but also hinders future expansions. This system does not only ensure neat appearance but also manages to prevent future expansions. It achieves an aesthetic appearance that is essential for a clean, professional workspace. It does this by efficiently managing the wires thus providing an aesthetic environment.

Boosting Long-Term Cost Efficiency

Although higher initial investment premium-grade solutions may have, the ultimate savings are colossal. Inferior materials break easily and thus require more frequent replacements, with high maintenance costs to go with them. Using strong, corrosion-proof alloys will decrease the number of times the system is likely to be repaired or replaced, thus ensuring many extra years of lifespan. With fewer energy wastes, more businesses will be efficiently managed with low expenses on electricity.

Supporting Industry Standards Compliance

Such installations have strict safety and performance regulations. Amongst the reasons for non-compliance may be the usage of sub-standard materials that will invite fines or even operational risks. High-quality solutions are designed for industry standards; hence, they ensure that the electrical systems installed remain legally compliant and safe to use for longer periods.

Elevate Performance with the Right Choice

Good-quality components are selected not only because they are more durable but because they have an impact on efficiency, safety, and longevity. The benefits here are huge because it will stabilize the structure of the electrical system, optimize the dissipation of heat, make it aesthetically pleasing, and reduce costs for maintenance. Businesses can, therefore, prevent system failures and reduce long-term expenses by using premium materials and well-engineered designs to keep a reliable electrical network.