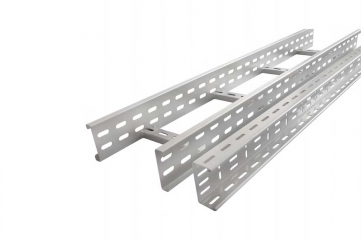

In the electrical infrastructure, safety is treated not as an add-on but as the most indispensable characteristic of any reliable setup. Indeed, the Top Ladder Cable Trays in India, by Super Cable Tray Pvt. Ltd., which manage and support heavy loads of cables, act as real custodians for the security, order, and safety of all concerned. Nevertheless, not all ladder systems will provide the same set of operations. It is commendable that technology, with a stringent safety policy, has made one aware of features that go a long way in safeguarding the cables as well as protecting the workplace.

Easy Accessibility For Quick Maintenance

Safety is not about avoiding accidents—it is about seeking responses when something goes awry. With proactive design features, it is possible to distinguish between routine maintenance tasks and a comprehensive operational shutdown. Open-construction designs for ladders make it easier for technicians to notice damaged cables, identify faults, and rectify the situation without having to disassemble large sections. This accessibility will translate directly into reduced downtime, exposure to hazards and a quick fix to any issues before they develop into major safety threats.

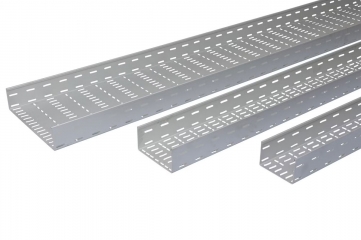

High Load-Bearing Capacity Ensures Safety

When cables are carried over long distances, their weight could impart tremendous strain to the cable support system. Therefore, a higher load-bearing capacity means that lighter Ladder Cable Trays can now hold several heavy cables without being intrusive to the extent of bending or even sagging back under dynamic loads. This helps prevent structural failure on the one hand and spares cable insulation from the brunt of excessive pressure or deformation on the other. An investment in trays that have been tested for maximum load capacity by an accredited lab will go a long way toward operational safety and system durability.

Corrosion-Resistant Finish Will Extend Life

Corrosion can jeopardize not only the aesthetic of the cable tray but also its ecosystem. In places such as factories where there is a lot of moisture, harsh chemicals, or outdoor conditions, the materials and coatings used are to be strong enough to resist corrosion. Whether it is galvanization, powder coating, or their stainless steel finish, preventing corrosion greatly increases the life of the trays without compromising their load-bearing capacity. This will, in turn, reduce the frequency of replacements, reducing safety risks and maintenance costs.

Anti-Slip Rungs For Technician Safety

Cleaning dust, oil, or moisture may make the ladder rungs very slippery when the technicians need access to the cables for inspection or repair work. An industry where every process is on a fast circuit, even a minor slip will surely result in delays and expensive safety incidents. Having anti-slip rung designs provides a firm grip to avoid the possibility of falling off and causing workplace injuries. This is critical for trays installed at a certain height and in hard-to-access areas. Hence, by making these surfaces safer, you are ensuring protection for the personnel engaged in their regular refinement.

Rounded Edges To Ensure Protection

One of the most neglected features is the edge design of cable trays. Very often, constant wearing of cable insulation by sharp edges puts them at risk of electrical faulting, short-circuiting, or even worse, fire. A standard-compliant Ladder Cable Trays Manufacturer will ensure that its products have smooth, rounded edges that prevent injuries and assist in easy cable movement during installation or readjustment. This feature directly supports cable layer integrity, which, in turn, helps with the overall safety of the electrical system.

Fire-Resistant Material For Critical Installations

The presence of flammable materials in the environment makes it a fire hazard. Such dangerous places could easily flare up from a small spark into a full-blown catastrophe if not properly contained. Trays made of fire-resistant metals or with special coatings may pose a risk of fire, keeping it from spreading through the tray's path. Fire-resistant designs not only fulfill building and safety codes but also provide peace of mind to sensitive installations such as chemical plants, oil refineries, or high-density data centers.

Safety Worth Your Effort

From the abridged aspects of an unparalleled load capacity, resistance to corrosion, fire protection, and smooth edges, the most recent safety features speak less like marketing lingo and more like the blueprint for a credible long-term performance. Selecting the proper ladder tray system means that the health of cables and the safety of technicians are its priorities. Whether it's a time-tested design by the Ladder Cable Tray or a product from a reputed Ladder Cable Tray Manufacturer, when safety takes precedence, enhanced durability, compliance, and peace of mind will always pay it back.