Exponential growth has occurred in the number of cables, occupying the high tech environments be it data centers, commercial buildings, or industrial plants. Reliable and scalable wiring systems demand the need for efficient cable management. A Raceway Cable Tray stands apart as a crucial solution providing not just functional but aesthetic and operational clarity in all wiring installations. Unlike loose cabling that can create clutter and safety concerns, raceway systems guide and shield cables in a clean, organized manner. This structure prevents tangling, reduces wear, and allows for easier upgrades or maintenance in the future key factors in industries where uptime and accessibility are critical.

Positive Safety and Regulatory Compliance

Structured cable systems will hence not be slow in producing benefits, with safety hazards being their primary category. Poorly managed cables often lead to overheating, possible tripping, and even short circuits. These cables may be well encased in raceway solutions from the physical damage and possible elements of nature as well as accidental fan contact. Moreover, these systems often ensure better compliance with safety codes and industry standards. The organized cable route directs air better, makes inspection easier, and minimizes the fire hazard, making it easier for facilities to be compliant with regulations.

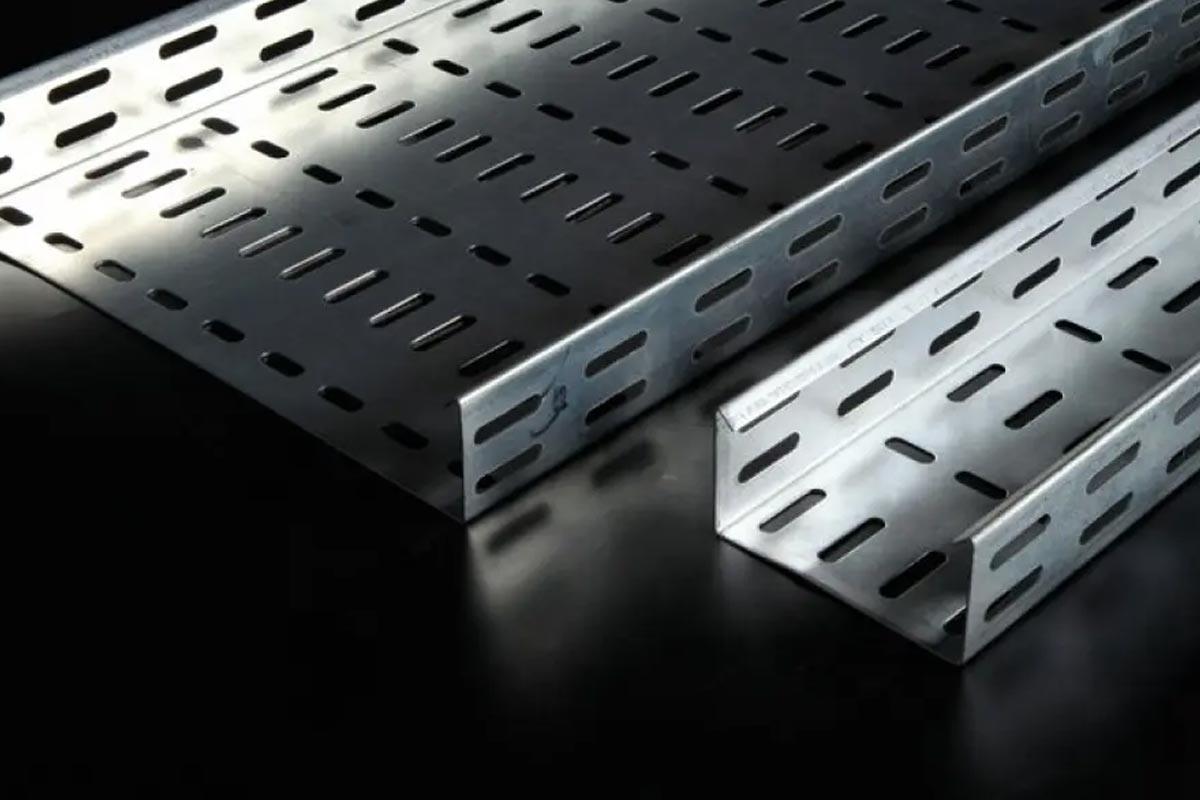

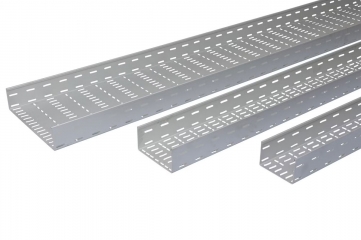

When Galvanized Trays Make Sense

In spaces where strength and protection from corrosion are a requirement, Galvanized Cable Trays offer an ideal alternative or supplement to a raceway system. These trays receive a zinc coat that acts as a guard against rust, wear, and tear and do well even when in environments often subjected to moisture, chemicals, or salt laden air.

Galvanized options appear especially practical for being outdoors or in industrial plants whose requirements are long life and low maintenance. These make heavy cables easy to support, and over time ensure the integrity of cables within. This makes it an option of choice in energy, marine, and infrastructure projects where the element exposure is inevitable.

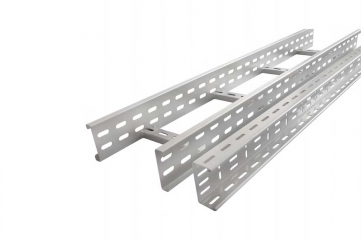

Ladder Trays for Heavy Duty Applications

Ladder Cable Trays are preferred if power cables with huge diameters are to be serviced for any high volume of cables. Their open, ladder like structure allows maximum airflow; hence an aid in cooling very high voltage systems or very data intensive systems. It also simplifies the tying, branching, and supporting of cables directly at regular intervals. Particularly practical for the solutions of large commercial or industrial setups, since loads can often pile up, ladders would overcome the cable drop at multiple points along the run. The Ladder Cable Trays from Super Cable Tray Pvt. Ltd. also has excellent mechanical strength ensuring low sagging or structural problems as time passes.

Adaptability and Future Development

One of the main attributes of raceway systems is that they grow with the plant. When a company expands its processes or adds new technology, the infrastructure supporting those systems must change. Raceway pathways give easy access to present cables and allow uninterrupted addition across ongoing works. This flexibility saves valuable time and labor costs when modifications are required in the future and renders the reconfiguration much less ominous than what it would have been without careful planning. Whether a new workstation or a server rack or even an entire production line is concerned, a well planned cable route serves that change without compromising safety or efficiency.

Wired for the Future: More Intelligent Reorganization

Cable management is efficient organization, but much more; it is the basis for safety and reliability and for long term operation economy. Raceway Tray provides neat organization for electrical systems; Galvanized Trays and Ladder Trays afford strength and flexibility in more specialized environments. Together, the systems form a complete structure for cabling, one that saves space, grows, and keeps systems as efficient as when first installed.