Neglected wiring management can force any maintenance team into a continuous war with tangles, wear, and accessibility issues. Indeed, the Best Cable Trays in India by Super Cable Tray Pvt. Ltd. function as more than a structure for cables—an investment in efficiency, safety, and long-term savings—facilitating easy repairs and making upgrades less troublesome. With easy installations, inspections, and servicing, they will make technicians' lives easier and ensure the reliable performance of electrical systems for years to come. As dependable as they may be, these trays showcase the most practical and forward-looking approach to them.

Safety Features Reduce Risks For Accidents

Electrical maintenance is more than just restoring faults—it's also ensuring safety for people. Properly constructed tray systems will include safety-based features such as rounded edges, which protect cables from abrasion; proper fastening systems to ensure that wiring is stable; and anti-slip surfaces wherein the wiring is suspended. These not only protect cables but also serve to provide safety to maintenance personnel working above or in confined spaces. High-voltage cables run above each other in factories and power plants; thus, such measures provide a low possibility of injury or damage to equipment. Given this, maintenance teams will not have to expose themselves to risky, unnecessary dangers while proceeding with maintenance tasks.

Neat Layouts Will Lessen Future Problems

One of the most practical ways cable trays can help reduce the hassles of maintenance is through organized layouts. If cables are properly arranged, it is very easy to identify, inspect, or change them in case of any problem. If there are tangled wires in the data center, troubleshooting time may be blocked, just as signal disruptions occur. The experienced Cable Trays Manufacturer in India knows this and designs trays that have proper spacing, clear routing channels, and even labeling options to minimize the time a maintenance team spends searching for the right cable. Additionally, having smooth edges further prevents damage to insulation and repair in the worst-case scenario.

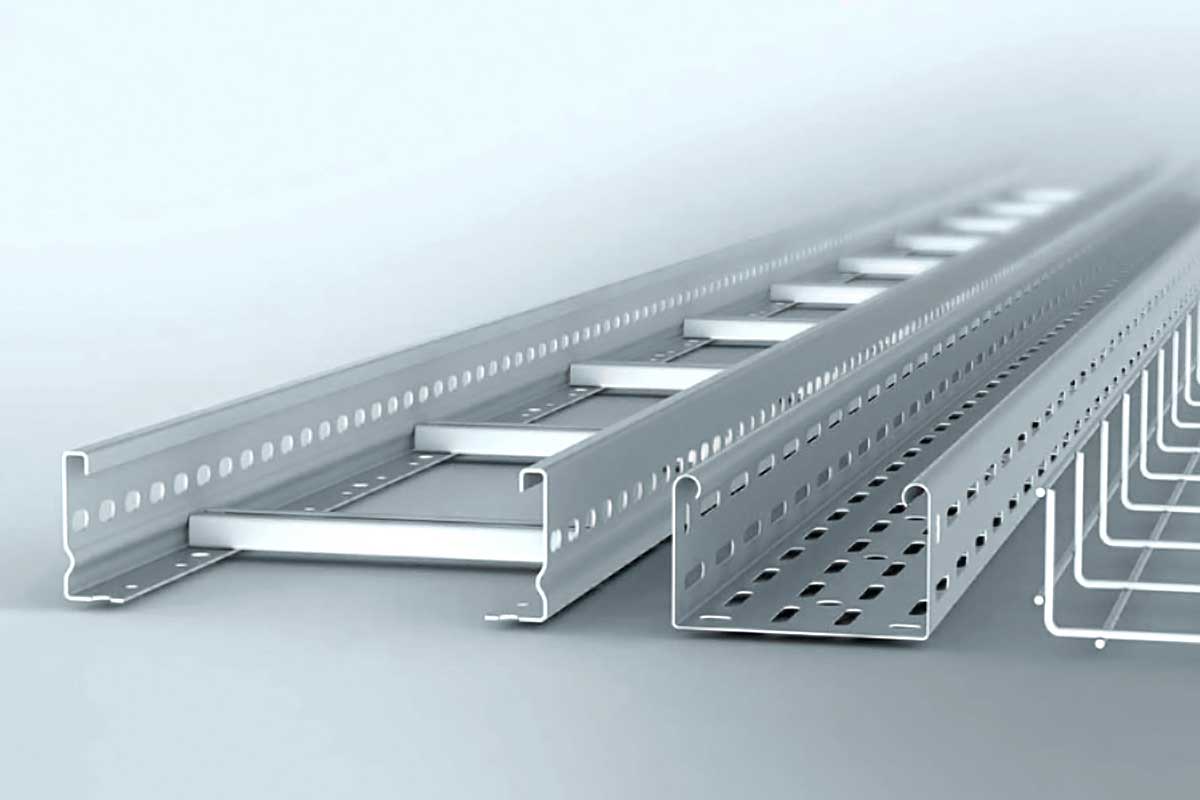

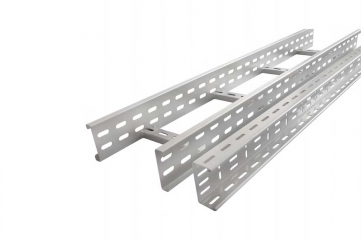

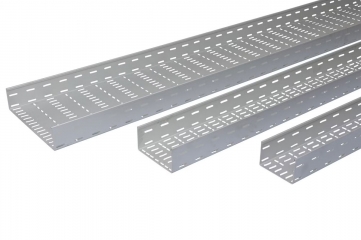

Toughness Avoids Many Changes

A hidden cost of cable maintenance is the replacement of damaged trays or supports. High-quality trays are made from galvanized steel, aluminum, or other robust materials that can withstand harsh environments. For instance, coastal areas where humidity and salt can corrode their galvanized finishes are protected from quick wear. In any heavy industrial setup, impact, vibration, and temperature variations can be defied through durable trays. This resistance leads to longer-lasting infrastructures, which demand fewer replacements or maintenance costs over the years. Durable trays tend to pay for themselves many times over in eliminating repeated expenses.

Workplaces Can Save Instances During Repairs

Time spent during maintenance translates into money, and any downtime is the enemy. In facilities with thick wires, technicians can trace problems through the setup without wasting time, which gives continuity to their operations and saves on lost production due to extended outages. Reliable Cable Trays are designed to open and free via a design that enables maintenance technicians to reach cables without stripping away walls, ceilings, or conduits. This aspect is valued in industrial plants where machines shut down or are not operational for an hour. Hence, accessibility offered by the trays enables just quick processing of repairs, replacements, or checks in the systems.

Scalability Will Reduce Headaches

The best looks towards the future, viewing it as the most immediate answer to its problems with today. Most cable trays are designed for adding cables or upgrading systems without major structural changes. The IT, manufacturing, and renewable energy sectors require this, especially due to rapid technology change, thereby leading to more needs for expansion. To avoid malfunctions, these makers provide after-sales support to reinstall everything in line for new systems. Maintenance teams will now be able to install new systems without disrupting them. Not only will that save money, but it will also absolve the hassles typically associated with large rewiring projects.

Smooth Maintenance & Less Headache

For industries where uptime is critical, cutting down on the maintenance hassle not only provides convenience but also protects productivity, safety, and investment. With an organized layout and easily accessible, long-lasting durability, built-in safety features and future scalability, the right tray can be the factor that ensures maintenance from a recurring problem into a smooth process. Finally, choosing the right trays means fewer distressing surprises and lost time as well as a more reliable electrical network—that is why trays are part and parcel of professional setup, performance and peace of mind.