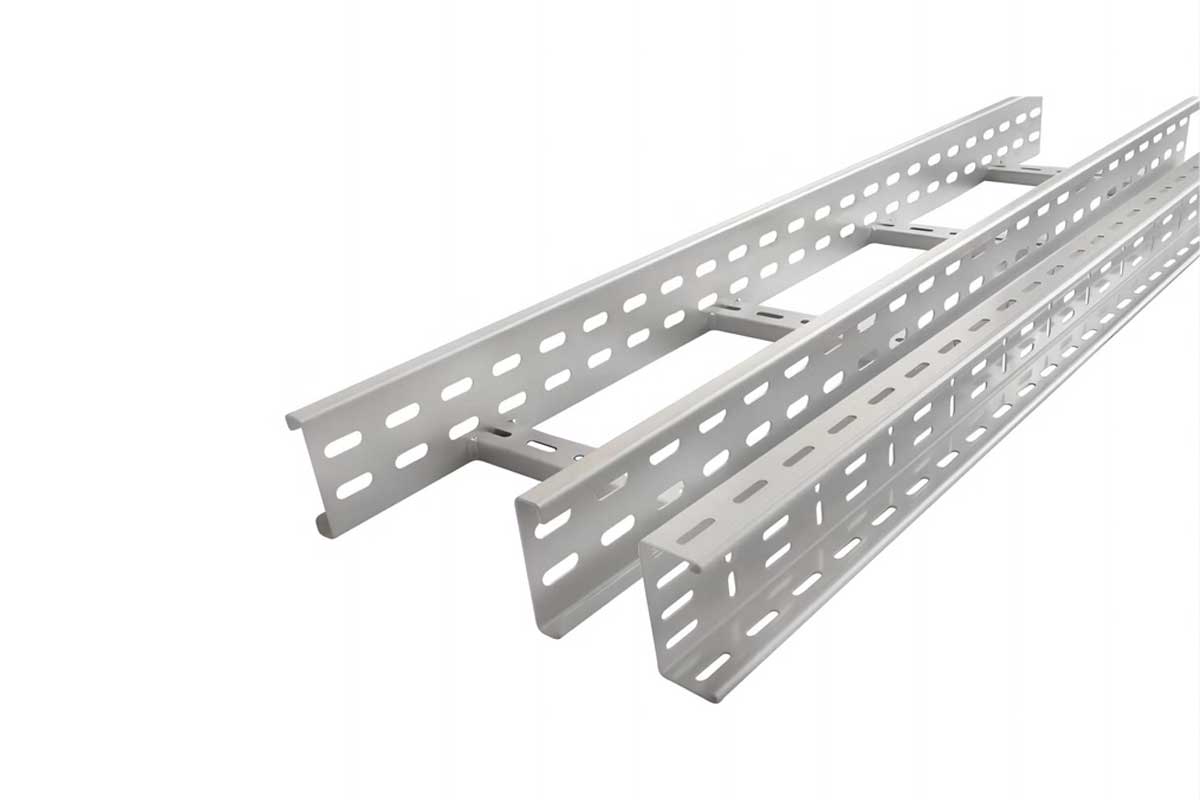

With the modern infrastructure comes a need for a cable management system that can efficiently, safely, and flexibly handle cables. When technology and industries advance rapidly, the way cables are organized, supported, and protected directly affects the operational effectiveness of all these systems. Out of all systems available, Ladder Cable Trays are the best option for many installations today due to their strength, their design features, and all the practical benefits they provide.

Made To Withstand Much Weight

Such trays, which have gained immense popularity, in fact, are the very best features that open up space for heavy cable loading without bending or warping under load. Its robust structure makes it perfectly suited to power plants, data centers, commercial complexes, and industries requiring thousands of meters of wiring to remain solid. Unlike other options, the design survives even in high-demand settings, providing long-lasting strength. In short, ladder trays are a solution that is not only sufficient for present needs but can easily be modified to accommodate future cable demands.

- High load capacity.

- Longevity in use.

- Strong structural support.

Simplifies Repair and Maintenance

Performance usually fades into irrelevance until a system gets an overhaul or troubleshooting. Open design ladder trays allow a technician to access, repair, or change cables without tearing apart the entire setup. This saves time and ensures an uninterrupted workflow during times when there is no room in the industry for hanging around without workflow. Ladder trays are comparatively more maintenance-friendly, unlike these closed alternatives, such as Raceway Cable Tray systems provided by Super Cable Tray Pvt. Ltd, which implies more stress and inefficiencies in repair operations.

- Quick fault detection during technical checks.

- Easily upgrades without dismantling trays.

- Saves costs as fewer laborers are required.

Overcomes Overheating of Cables

Cable safety comes first, especially in heavy-duty applications when wires are permanently under stress. Ladder trays are designed in a way that no heat gets built up; therefore, they are able to sustain the performance of the cables throughout their lifetime. Thus, reducing heat is crucial to avoid insulation damage or failure of the entire system. Ventilation alone makes ladder trays much more reliable than all closed systems, where heat is trapped and very often jeopardizes the integrity of the cable.

- Support natural airflow.

- Overheating protection.

- Increased lifespan of cables.

Balances Affordability with Performance

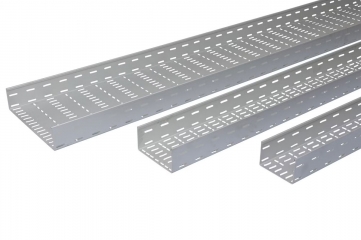

Though strong, built, and long-lasting ladder trays are also a balance between low cost and performance. According to most other alternatives that demand high-strenuous work, this form of installation is much shorter and requires less labor. Scalability is another important point where these trays allow organizations to expand their cable networks without any added complexity. Such trays are much lighter and flexible in design and generally favored in cost-sensitive environments that still prioritize reliability, although the more commonly used and cliometric preferred Galvanized Cable Trays are among the most relied-upon products.

- Install faster, hence significantly reduce delay and cost.

- Adaptability makes them fit for new projects and future expansions.

- Lower ongoing maintenance: Excellent returns in the long run.

Endorsed by Industry Leaders

The global preference for ladder trays is backed by their adoption in industrial, commercial, and technological sectors. They present performance, safety, and adaptability-a hallmark of demanding environments. We assure quality Trays manufactured to strict performance metrics trusted by several industries as a result of their durability and efficiency. Choosing a proven manufacturer strongly reinforces the confidence given by industries in their cable infrastructure, as well as deepens the assurance that an industry is getting a system based on long-term performance and safety considerations.

- Proven track record of performance

- Reliable and consistent quality

- Trusted by huge operations.

Final Thoughts

The efficiency of these trays makes them very competitive in a market that must have performance and safety seamlessly jiving with cost management. Such a durable system supports a large amount of cable runs; easy maintenance is designed to reduce the risks of overheating, both critical aspects of operational safety. The cost-effective and hyperflexible embodiments generally outperform most closed systems available in the market today. Be it for industrial plants or technology hubs, or simply growing businesses, ladder trays are at the forefront of proven and practical solutions in assuring reliable cable management systems over the years to come.