In modern electrical installations, the safety and longevity of wiring systems have to be assured. Overheating and damage to the wire are some common problems that cause major electrical failures, high repair costs, and even some safety hazards. The structured wiring management system in the form of Cable Trays is the best way to solve these issues. These systems provide organized routing besides helping in the dissipation of heat efficiently.

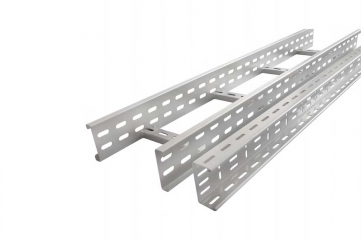

Effective Air Circulation for Heat Dissipation

One of the major ways in which structured support systems prevent overheating is by providing sufficient air circulation around the wires. Unlike enclosed conduits that restrict airflow, open-framework designs allow heat to dissipate naturally. This continuous airflow minimizes the buildup of heat, thus not likely to damage insulation and perhaps create short circuits. Perforated Cable Trays, in fact, are good ventilation solutions. These are designs that have uniformly distributed holes in order to promote greater airflow. As such, they will allow hot air to get out and stop hot spots within the wiring system from developing. They are suitable for high electrical load management in data centers and manufacturing plants.

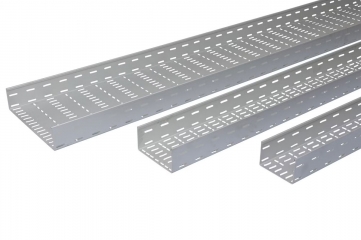

Avoiding Wire Insulation Damage

This weakening can make wire insulation cracky and wear off with time under excessive heat as well as through external environmental exposure. The results of such damage are short circuits, electrical failures, and even fire hazards. Cable support systems maintain proper spacing in an efficient way and do not expose wiring to direct sources of heat, extending the lifespan of its insulation. Perforated designs are especially beneficial in this regard, as they allow for flexible cable routing while preventing the wires from being tightly packed. This reduces thermal stress and makes inspections and maintenance accessible when needed.

Organized Layout Reduces Wire Clutter

Overcrowded or tangled wires may produce excessive heat, which damages the insulation and results in performance inefficiencies. A well-structured support system ensures that electrical cables are neatly arranged, spaced appropriately, and secured in place. This organized layout helps reduce physical stress on the wires, which in turn prevents overheating and potential breakdowns over time. A Raceway Cable Tray from Super Cable Tray Pvt. Ltd. is good for achieving a structured cable management system. It is designed to enclose and protect wiring that will run through its length. Raceways provide a coordinated pathway for wires, preventing them from entering dust or getting accidentally physically damaged. Even though raceways are enclosed in nature, they often integrate designs that help in allowing limited ventilation to help control the amount of heat generated.

Load Distribution And Weight Management Support

A long run of electrical wiring in very large installations may become very heavy and therefore cause strain on the insulation and connection points. An adequate cable management system will therefore distribute the weight evenly, reduce mechanical stress, and thereby prevent insulation wear. Proper support systems will keep the wires free from sagging and bending, which otherwise can result in damaged insulation and overheating.

Increasing Fire Safety Measures

Effective cable management is a crucial fire prevention measure. Poorly managed electrical wiring may cause overheating to turn into a fire incident, thereby endangering human life and property. Open-framework solutions not only help in dissipating heat but also provide for the easy mounting of fire-resistant coatings or barriers. Moreover, the ability to inspect and maintain wiring regularly adds to a proactive fire safety strategy.

Compliance with Safety Standards

The electrical installation standards set by the regulatory bodies are stringent. It calls for the cable management so that there is a lesser chance of overheating and damage. Adoption of raceways or perforated designs would make the solutions adhere to industry regulations, hence providing a safer workplace environment.

Final Review

Investing in a good wiring support structure is crucial for preventing overheating and damage to the wires. The right solution would be between open-structured or enclosed systems, depending on the application and environmental requirements. The perforated designs are suitable in high-heat environments, but the enclosed raceway systems also offer protection from external influences. By appropriately choosing the solution for electrical installations, businesses and persons can ensure efficient, safe, and long-lasting wiring. Prioritizing such a solution will eventually enhance operational efficiency while minimizing any maintenance costs that may be needed and potential hazards in the longer run.