Over the past few years, the growth of Delhi’s infrastructure has been nothing short of spectacular. The infrastructure growth of Delhi, ranging from commercial hubs and residential complexes to data centers and public institutions, requires cable management systems that are not only efficient and long-lasting but also safe. Besides, the electrical installations must be made in a way to endure the changes in temperatures, pollution, moisture, and loads. So, deciding the ideal cable support system is far from being just a choice; it becomes a necessity to make sure that the safety and the performance over time are maintained. Now, in a lot of modern installations, Galvanized Cable Tray systems have gained so much popularity that they are considered to be the foremost option. This is mainly because, even under very harsh conditions, they can still keep their structural integrity.

Why Galvanization Matters for Cable Management

Exposure to external agents—dust, moisture, chemical residues, and environmental pollutants—is a daily occurrence for cable trays. Besides, corrosion, which can go all the way to the dismantling of the installation can still contaminate the safety system of your metal components if they are not well coated. As a result of galvanization, a layer of zinc is produced for the metal which is not only wear and chemical reaction resistant but also inert to environmental degradation. In this way, galvanization not only keeps the strength of the trays but also provides them with their long-term functionalities with very little upkeep required.

The paint sticks to the surface in such a manner that it prevents any kind of chipping or scratching. Through this, the base metal being fully protected, maintenance cycles are minimized and, consequently, the life of the tray system is extended. For infrastructure projects situated in Delhi and emphasizing aspects such as durability, resistance to corrosion and cost-effectiveness, galvanized trays represent a wise and economical choice.

Applications Across Industrial and Commercial Sectors

Cable trays in Delhi are used in different ways to meet the requirements of various industries. In the case of skyscrapers, they are used to simplify the wiring system of several floors. In data centres, they are the backbone of the structured cable networks that need to be exact and reliable. On the other hand, production facilities employ them to manage the complicated wiring that is exposed to the vibration of machines and industrial waste products. They are also an integral part of public infrastructure such as hospitals, transport terminals, shopping complexes, and corporate offices, which utilize them to maintain the safety and comply with electrical standards. Their flexibility allows them to be used not only in big projects but also in small installations.

Strength and Load-Bearing Advantages

Galvanized trays have both the characteristic of corrosion resistance and are also acknowledged for their stability from the structural point of view. Such trays can hold a heavy wiring bundle, fibre optic cables, and power lines without changing their shape or bending. The durability of the metal when combined with the galvanic coating help the tray to stay strong in an environment which is tough.

Those trays are the first choice of engineers and contractors due to them complying with safety standards and being able to easily integrate with other accessories. As the change in the electrical distribution systems with higher data loads and automatization continues, the necessity of having a reliable cable support as part of the planning and execution process becomes more apparent.

Design Flexibility for Complex Layouts

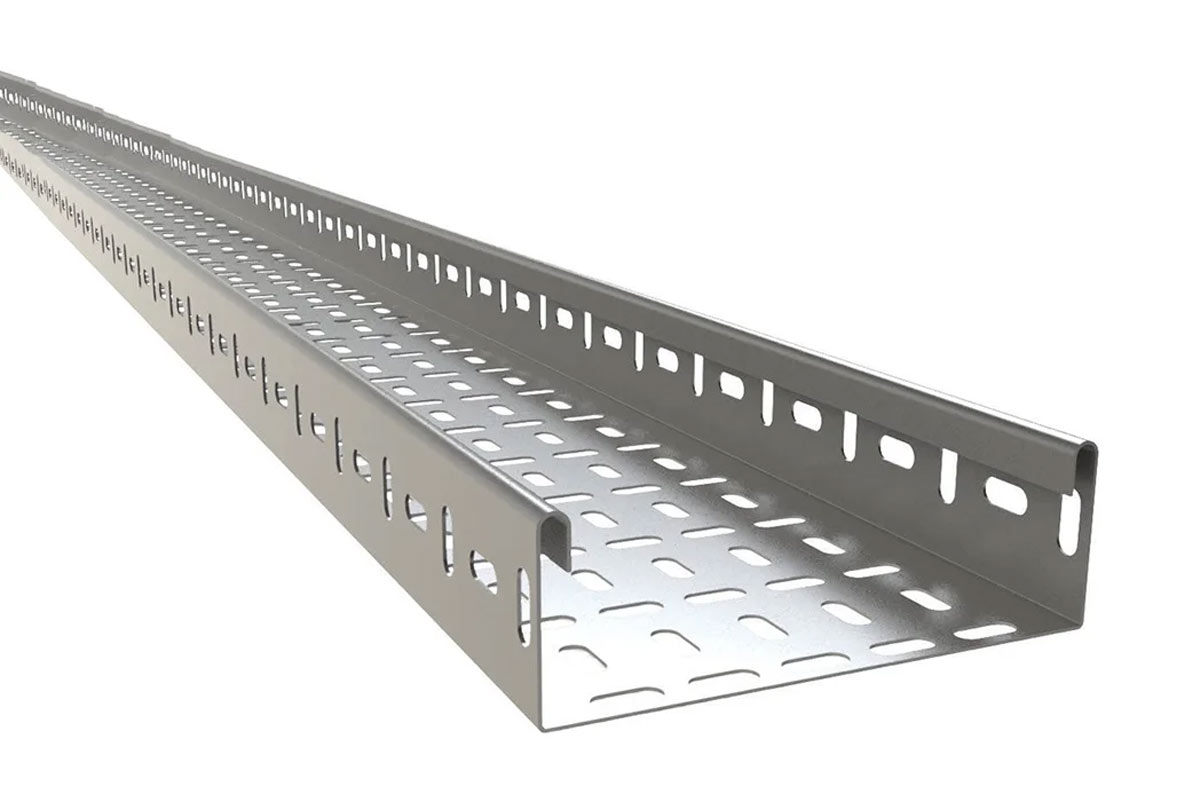

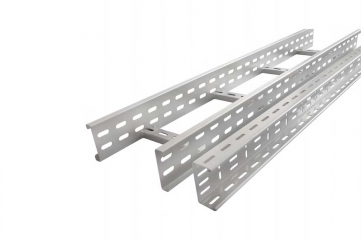

Routing in modern cable management is no longer restricted to the straight line. Such installations are frequently in need of bends, intersections, vertical drops, and branches that can be managed easily. The trays which are well designed not only make such configurations possible but also ensure that the accessibility and security are maintained. The Perforated Cable Tray is among the most popular types of cable trays, providing better ventilation, easier cable tying, and reduced total weight. These characteristics make it possible to keep a good flow of air, a lower temperature of cables, and also facilitate the checking and changing of the installation when required.

Integration with Industrial Standards

Electrical contractors and builders in Delhi often prioritize compliance with national and international standards. Properly galvanized trays meet quality norms related to coating thickness, metal gauge, and recommended load conditions. They are compatible with earthing accessories, fittings, and support brackets, ensuring seamless installation and system continuity. The protective layer also minimizes the chances of rust leaching, which can otherwise pose risks to surrounding components and building structures. Whether for renovation or new construction, adherence to these standards improves performance and safety.

Suitability for Challenging Environments

Several industrial units around Delhi operate in conditions where temperature and humidity fluctuate. Galvanized trays withstand these stressors better than uncoated alternatives. They resist oxidation even when exposed to water, chemicals, and dust, which is essential for ensuring the integrity of wiring networks. They also support a cleaner and more professional appearance in settings where visible installations matter. For long-term use in humid basements, rooftop conduits, or multi-level commercial complexes, these trays provide stable and consistent performance.

Role of Manufacturing Quality and Accessories

The level of functionality for a cable tray system is very much dependent on the accuracy of its production. Using advanced equipment, choosing superior metals, and following rigorous quality controls lead to long-lasting products that are even throughout the series. Finishing of the highest quality also serves to stop at edges that may be cutting the cable sheath. The likes of bends, reducers, clamps, and junctions, which are the components of the cable tray system, not only strengthen but also extend the working framework. Along with easy installation and thus future scalability, these accessories enable the systems to become larger without a large change. The modular design thus guarantees a more accommodative and flexible upgrade.

A Trusted Name in Cable Management

When selecting a supplier, reliability and product standards matter. Companies providing specialized trays ensure that their offerings cater to multiple types of settings. Here, the name Super Cable Tray Pvt. Ltd. appears alongside the term Gl Perforated Cable Tray, indicating the availability of corrosion-resistant and efficiently designed options under professional guidance.

Cost-Effectiveness and Long-Term Returns

Despite the fact that the initial price of treated metal is generally a little bit more than uncoated alternatives, the protection and savings over time really make the investment worthwhile. Reduced maintenance costs, less part replacement, and increased safety are the main advantages that one can convert into significant monetary savings over a period of time. Such trays find favor among industrial and commercial users as they are almost fully resistant to the processes of deterioration. In such cases as the expansion or relocation of the business, these trays, if they are still in good condition, can be reinstalled with the assumption that there will be almost no performance loss.

Looking Ahead: Sustainable and Secure Solutions

For the expansion of the city of Delhi, the development of its infrastructure will still depend on such systems which are not only strong but also environmentally friendly. In this regard, galvanized trays are a good step towards sustainable building practices as they not only prolong the productive life of wiring pathways but also reload less waste of materials over the years. Such a performance under different conditions makes these trays very popular among the users as they can easily fit the accessories and standards required, hence they remain one of the most convenient and safety ways to arrange, protect and distribute cables both electrical and communication in the areas that are changing technologically.