Ever tried tracing a faulty wire in a jungle of tangled cables? It is like finding an electric eel. Frustrating, risky, and not fun. That, in workplaces, costs one time more than patience, but it can drain money budgets much faster than you can say "short circuit." So, choosing the right support system has become less "where do we put the cables?" and more "how do we keep costs down for years to come?" A reliable installation is not just where wires dangle. What these Cable Trays mean is that they are a prudent instrument of protection, organization, and, most of all, assets in the long term.

Organized Cabling Saves Time & Money

Disorganized wiring leads to increased repair times, frequency of fault occurrence, and higher maintenance costs. When cables are properly routed through an organized support system, technicians can easily gain access to the wiring, trace down the source of the problem without wasting precious hours untangling or tracing wires through this messy setup, and finally tackle the problem. Organized pathways also help prevent unnecessary forces and bends in the cables, which can damage the insulation and outages. This resulted in fewer service interruptions and time for troubleshooting. Over months, even years, this arrangement accounted for savings on repair and downtime costs.

Added Protection Against The Hazards

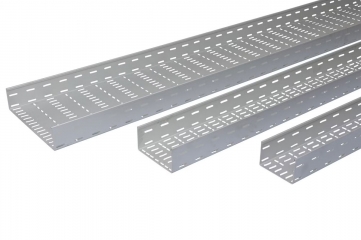

Moisture, dust, and fluctuating temperatures are common elements that a cable might encounter, not to mention the chemical environment that could affect its service life. A well-designed support solution, such as Raceway Cable Trays by Super Cable Tray Pvt. Ltd., provides a protective enclosure that keeps cables away from the damaging factors mentioned. With thinning, abrasion, and insulation deterioration, all can be minimized by that additional barrier. By avoiding exposure to threats, extending the electrical system's lifetime, reducing the number of replacements and emergencies, and having longer periods when the system can be relied on to work with dependability and save money.

Built for Extensions & Improvements

Whenever a facility undergoes growth or advancement in technology, higher electrical demands will follow. The cable support system, being reliable from the inception, prepares the grounds for future expansion that is easier and cheaper. Modular and scalable designs enable new cables with virtually no reconstruction or support for expensive retrofitting. This even saves dollars during expansion but ensures that the infrastructure will be well-fit to meet future requirements without disrupting existing systems. In terms of industries having rapid high growth, this becomes a significant long-term cost advantage.

Easy Access For Speedy Maintenance

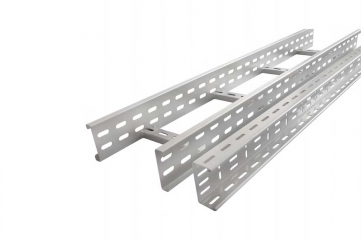

Two factors determine the way a cable flows: the cable’s dimensions and the length of the cable. Open but solid construction, such as Gi Perforated Cable Trays, permits easy accessibility for technicians—the substitute allows the cable to be easily identified, replaced, or redirected without opening broad areas of the installation. The time factor involved and the resolution of faults will subsequently be lower, also reducing the cost of downtime effects. Add in the quicker fixes, and there's less loss of productivity during redundant procedures, which matters a lot in facilities where productivity is wired directly to their continuity.

Ameliorating Compliance & Safety Risks

Neglecting or poorly maintaining wired systems presents safety hazards, causing electrical fires, short circuits, and even total malfunctioning of the system. With these lockouts, the total costs incurred due to repairs would run in the millions, alongside horrific penalties, legal implications, and other damages to a company's reputation. A compliant cabling support system mitigates risks by providing wired systems with protection and order. An establishment with such a system is likely to remain in compliance with various industry standards and safety regulations while avoiding fines, liability, and expensive emergency responses.

The Long-Term Cost-Wise Route

Proper installations are more than just holding cables; they protect your investment, cause minimal future intervention, and are flexible enough for future modifications. Organizing, protecting, and making wiring accessible will reduce the frequency and costs of repairs due to environmental destruction and generally ensure that scalability continues smoothly. So, whether you use encased systems, such as Raceway Cable Trays, or open designs like Gi Perforated Cable Trays, it communicates a clear message: money spent today means a lot more in savings tomorrow. Think even farther than just supporting lines; think about supporting a bottom line year after year.