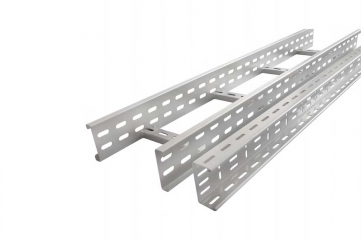

In the rapidly changing industrial world of today, Ladder Cable Trays are essential for creating the electrical infrastructure of the future, which is safe, scalable, and of high-performance. These systems, which are designed to meet the heavy cabling requirements of the operation, have spread to be a vital tool in the whole ecosystem of the manufacturing industry, power generating units, data processing facilities, and significant commercial sector projects. Their industrial, strength, air circulation-friendly structure, and long-span feature make them an excellent option for those industries that are a going concern and are looking to strengthen their business for the long term.

Massive Load-Bearing Capability

Industrial surroundings put cable management devices to the test in terms of their ability to carry hefty loads while also maintaining safety. Among the cable management solutions, ladder-type ones are made to handle thick power cables and wiring in a bundle over a long stretch of the area. They have strong side rails and the rungs that are equally spaced can easily carry the load because the weight is distributed evenly, thus, that the sagging is kept at a minimum and that the performance is at a stable level even in situations of continuous operational stress. Hence, it is a good fit for a manufacturing plant, substation or the area in which heavy machinery is used where the point of interchangeability is a reliable source of power.

Superior Heat Dissipation for Cable Longevity

One of the major benefits of ladder-based designs is their openness. This feature makes it possible for the air to flow freely around the cables. In the case of a high, current application, the overheating of the cable can cause the insulation to fail and the performance to be lowered. The ventilated version is geared at keeping the cable at the right temperature thus, its service life is extended and the maintenance risks are reduced. Such thermal performance is of paramount importance in places that operate continuously or experience varying loads of power.

Durability in Harsh Industrial Environments

Industrial environments usually subject the plant to dust, moisture, vibration, and corrosive agents. Ladder systems are usually made of galvanized steel, aluminum, or stainless steel, hence their good resistance to corrosion and mechanical wear. The solid construction of these products ensures the protection of the cables in the long run while it is still structurally sound, even in situations like a chemical plant, refinery or coastal area.

Operational Flexibility and Easy Maintenance

With rising businesses, the need for more cabling in different industries becomes more complicated. Ladder-style layouts give the most flexibility for upgrades and changes. In fact, without tearing down the whole installation, you can add, remove, or reroute cables, thus saving time and lessening the downtime. Maintenance teams also have a great advantage because they can easily see and reach the place, thus enabling them to do fast checks and solve troubles, which is operational efficiency at the same time.

Key Advantages That Drive Industrial Preference

The ladder-based systems are still the leading ones in industrial cable management due to the fact that they provide a proper combination of strength, safety, and adaptability. Their structure is a support both for current operations and for the future scalability.

The major benefits are:

- High load-bearing capacity for heavy power and control cables

- Enhanced ventilation to prevent overheating

- Long-span support reducing the need for frequent supports

- Simplified cable routing and future expansion

By these characteristics, they are a dependable support for complicated electrical networks.

Modern Cable Management Solutions

Though ladder concepts work best for heavy load applications, companies use them together with different systems to satisfy their specific routing or space needs. For example, Super Cable Tray Pvt. Ltd. provides engineered solutions that complement ladder systems with alternatives such as Raceway Cable Tray configurations helping in cable segregation organization in areas that require enclosed or surface-mounted pathways. This combined method gives industries the freedom to draft the complete cable layouts without safety or visual appearance being compromised.

Compliance, Safety, and Industry Standards

Safety rules and electrical codes that are put in place to ensure the safety of people emphasize proper cable routing that should be organized and accessible. Ladder systems are a means through which facilities can abide by the set standards as they keep the cables off the ground, visibly arranged, and safe from any kind of physical damage. Besides that, segregation properly done is also a measure in reducing fire risks and making the work of auditors easier thus making them the most favored in highly regulated sectors like pharmaceuticals, energy, and data infrastructure.

Where Ladder Systems Deliver Maximum Value

Such systems have been adopted worldwide in different sectors that require them to be reliable and scalable. Their use has gone beyond the production factories of the past and is now encompassed by modern infrastructures.

Those areas where such systems are commonly found include:

- Production plants and facilities of automation

- Power generation and renewable energy projects

- Data centers and hubs of IT infrastructure

- Commercial complexes and industrial warehouses

This, along with their adaptability across sectors, is what highlights their long-term value.

Complementary Designs to Meet Different Demands

If an installation requires the control of airflow or partial enclosure, the choice of Perforated Cable Trays as an alternative to the ladder layout is usually due to the presence of both types there. This mixture ensures that each part of the building takes advantage of the most appropriate cable management solution while the rest of the system remains in harmony and performs well.

A Strategic Investment for Industrial Growth

Choosing the right cable management infrastructure is not just a technical decision, it is a strategic investment. Ladder-based systems support uninterrupted operations, simplify future upgrades and enhanced safety. With rising power demands and smarter industrial facilities, investing in high-quality solutions from Super Cable Tray Pvt. Ltd. ensures long-term efficiency, reliability, and peace of mind for industrial stakeholders. By prioritizing strength, ventilation, and adaptability, ladder-style cable management continues to define the foundation of modern industrial electrical systems.