Modern Cable Tray systems are essential for a safe, orderly, and durable electrical installation in industrial infrastructures. These systems, which are designed to carry power, control, and communication cables, give a facility a well-organized way that increases operational efficiency and at the same time protects cable insulation from both mechanical and environmental stress. As the number of industries grows and so does the demand for electrical power, the need for reliable cable management solutions has become a necessity in manufacturing units, commercial facilities and infrastructure projects.

How Cable Trays Help Industrial Cable Management

Industrial plants are heavily reliant on electrical networks, which are complex in nature, to run machinery, automation systems, and safety equipment. Cable trays act as a strong structural support system that keeps the cables in a position that is both fixed and raised, thus, cables are shielded from unnecessary bending, twisting or entangling. By ensuring correct routing and allowing for the right spacing, trays lessen the physical forces that the conductors and the insulation are subjected to, which is directly linked to the extension of cable life and the achievement of a stable system performance level.

Structural Support and Load Distribution

One of the primary functions of cable trays is to manage the physical weight of cables over long spans. Properly engineered trays distribute loads evenly, ensuring that cables do not sag or experience pressure points that could weaken insulation over time. This structural stability is especially critical in industrial plants where heavy-duty power cables are used continuously under high electrical loads.

Protection of Cable Insulation

Cable trays protect insulation by keeping cables away from harsh floor-level conditions such as moisture, chemical spills, dust accumulation, and accidental impact from machinery or foot traffic. Elevation also minimizes the risk of rodents or mechanical damage. In addition, trays help maintain the minimum bend radius required for cables, preventing internal conductor damage and external insulation cracking.

Thermal Management and Heat Dissipation

Good heat dissipation is a must if cable performance and safety are to be kept at priority. The use of open cable trays brings fresh air to the conductors, thus the heat that has been produced during the operation is able to dissipate by itself. This ventilation prevents overheating which is the main cause of insulation degradation in industrial environments. With the increase of electrical loads, correct thermal management is a decisive factor for system reliability.

Some of the main thermal benefits are:

- An enhanced airflow that helps to dissipate the heat

- Stable operating temperatures for continuous, duty cables

- A Lower risk of insulation hardening or premature failure

Material Strength and Durability

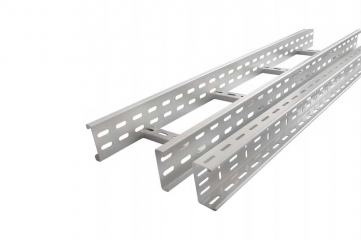

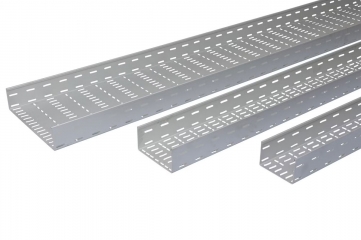

Industrial cable trays are manufactured using high-quality materials designed to withstand demanding conditions. Systems offered by Super Cable Tray Pvt. Ltd. are engineered to deliver durability, load-bearing strength, and corrosion resistance for long-term use; particularly, options such as Gi Perforated Cable Tray solutions combine structural strength with ventilation benefits, making them suitable for high-density cable installations in factories and commercial complexes.

Flexibility and Future Scalability

Different sectors change over time and as a result, they have to upgrade, expand or reconfigure their electrical systems regularly. With cable trays, it is very easy to add, remove, or reroute cables because they provide access to the cable runs without any kind of intervention in the existing infrastructure. The said flexibility has a great impact on the reduction of the downtime and labor costs as opposed to the closed conduit systems which are the main reasons why trays are considered to be a future-ready solution for growing facilities.

The operational benefits are the following:

- Inspection and maintenance are made very easy through the access points

- System upgrades and expansions become less complicated

- Installation time is shortened when there are modifications

Safety and Compliance Standards

Cable management system configurations are a major factor in enhancing safety at the workplace and ensuring that the set rules are adhered to. Well-planned cable routing eliminates the possibility of workers tripping over the cables and lowers the chance of electrical faults resulting from tangled or damaged cables. Moreover, the correct grounding of metal trays makes available a safe way for fault currents, thus, both equipment and staff are protected. The above mentioned elements equip the different sectors with the needed tools to facilitate compliance with electrical standards of safety at the national and international levels.

Corrosion Resistance and Longevity

Where there is exposure to moisture, chemicals, or outdoor conditions, corrosion resistance is the feature that is most required. A Galvanized Cable Tray is able to prevent rust and thus, prolong the service life of the system by giving an additional layer of protection to the metal through zinc coating. The stated durability keeps the system performing continuously even in tough growing industries, thus maintenance cost is reduced gradually.

Some of the benefits that a corrosion resistant tray has:

- Longer operational life

- Lower maintenance and replacement costs

- Uninterrupted performance in harsh environments

Why Choose a Trusted Manufacturer

Simply choosing the most attractive cable management system is not enough. One must also consider the manufacturing quality and the engineering expertise. Super Cable Tray Pvt. Ltd. is all about providing precise engineered solutions that are in line with the current industrial requirements. By focusing on the quality of the material, the load calculations, and the installation efficiency, the company enables the industry to construct safe, scalable, and efficient electrical networks.

Conclusion

Cable trays are an essential part of the industrial electrical infrastructure without which it would be structurally unsupported, the insulation would be unprotected and it would lack thermal efficiency and long-term reliability. Besides these features, cable trays make it possible to organize the routing of cables and to easily scale the system which, in turn, ensures that the industry can continue to operate safely and efficiently while being prepared for future growth. Investing in a good cable management system is tantamount to making a wise investment as it guarantees that the cables will be safe, readily available, and in compliance with the regulations.