In the present-day manufacturing and commercial setups, Ladder Cable Trays are essential for safety, maintaining system stability, and ensuring the smooth running of operations. With an open-rung layout, these trays are made to limit the build-up of dust, moisture, heat, and any kind of toxic substances that may hurt the electrical networks. As 2025 advanced the complexity of the facilities, the industries that require clean, well-ventilated, and easily inspected cable management systems realize how crucial this design feature is becoming.

Understanding the Open-Rung Design Advantage

The main characteristic of ladder-style systems is their openness or lack of a continuous surface found in solid-bottom ones. This openness of the structure thus enables gravity and air movement to be natural, thus preventing the settling of the unwanted materials in the cables. This configuration is a great performance enhancer in a high-demand environment while at the same time it is a huge maintenance challenge and safety risks reducer.

Preventing Dust and Debris Accumulation

Dust build-up is a major problem that is common in industrial facilities such as the textile units, woodworking plants, and grain processing centers. The fine particles can become a source of combustion very quickly if exposed to heat or electrical sparks. Ladder-style systems solve this problem in an efficient way by allowing the dust to fall through and thus, it doesn't collect in the cable path.

Some of the main advantages are:

- The dust naturally falls through since there is no solid base

- The fire risk is minimized as a result of the reduced buildup of combustible particles

- Cleaner cable routing paths that facilitate housekeeping and audits

Such a self-cleaning operation is what makes ladder-based systems the most suitable ones for environments with a high level of dust.

Managing Moisture and Condensation Risks

Moisture is another major cause of damage to the electrical network, which is prevalent in humid, outdoor, or facilities that are washed regularly. Typically sealed units may trap water inside, which results in rust and insulation damage. Uncovered ladder trays provide a way for the liquid to flow immediately, thus, no water remains and there is no risk of long-term exposure to moisture. As a result of the removal of water that may be found in some places, these systems are useful in preserving insulation and in lessening the chances of short circuits. Thus, they are excellent food processing units, chemical plants, and outdoor installations where condensation and washdowns are regular.

Reducing Heat Accumulation for Safer Operations

One of the most underestimated sources of heat buildup, which in turn may bring about serious damage to electrical systems, is the accumulation of heat in the cables. When cables are used at full capacity, the heat trapped inside can cause insulation to be damaged and the current-carrying capacity to be lowered. The ladder configuration allows for heat to be constantly removed from the cables as the air is free to flow around them.

Advantages of better thermal management are:

- Stable and normal operating temperatures of both power and data cables

- Longer cable life and less insulation breakdown

- The ability to raise the ampacity without the risk of the cable becoming overheated

This heat efficiency is the main reason why the operations are safer and their stability is increased.

Preventing Hazardous Gas Concentration

Gases that are both flammable and toxic in nature, which are released in industries like oil and gas, petrochemicals, and pharmaceuticals, can become a major source of danger to people's lives. Those can be the cases where systems that are tightly closed can unintentionally cause the gases to be channeled or trapped, increasing the risk of explosions. When cables are routed openly, the gases can dissipate naturally into the atmosphere. The fact that the design is such reduces the production of concentrated gas pockets that could be close to electrified lines and thus helps in conforming to the strict industrial safety norms and minimizes the possibility of drastic incidents.

Discouraging Pest Infestation

Rodents and birds are a problem that can be found in any situation, and in this case, they usually look for enclosed, dark places for nesting, which eventually leads to the insulation being chewed and sudden situations of failure. Open-rung systems do not provide any shelter for animals, so they are much less attractive as places for building nests. Besides, the visible layout makes it possible to quickly notice any budding infestation that takes place at the time of routine inspections. Such exposure allows for a quicker response to the problem and thus ensures the continuous functioning of the systems in big facilities is kept.

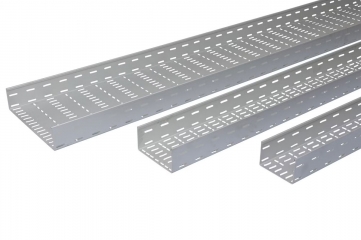

Material Strength and Corrosion Protection

When manufactured using corrosion-resistant finishes, ladder-style systems deliver long-term durability even in aggressive environments. Super Cable Tray Pvt. Ltd. offers robust solutions developed with industrial-grade materials, including options comparable to a Galvanized Cable Tray, ensuring resistance to rust, moisture, and chemical exposure. This combination of strength and openness supports both structural integrity and accumulation prevention across diverse applications.

Supporting Compliance and Maintenance Efficiency

Present-day regulations put a major focus on aspects like hygiene, access, and safety of the electrical installations carried out. An open-rung structure makes the adherence to these standards easier since the cables are kept off the ground, neatly arranged, and the whole process of checking is quite straightforward. Repair personnel are in a position to quickly spot the problem, put in new cables, or change the configuration without taking apart the whole system, which is the case if one decides to go with an enclosed alternative such as a traditional Cable Tray.

Some of the maintenance-oriented features are:

- Visual checking of cables made simple

- Cleansing becomes quicker and there is less downtime

- Expansion becomes more flexible and existing lines are not disturbed

Such benefits, in turn, imply lower lifecycle costs and sustained continuity of operations.

Conclusion

Preventing accumulation is a necessity rather than a choice in the rapidly changing industrial world of modern times. Ladder-style systems with their minimalistic design and high operational efficiency are capable of resolving the mentioned problems simultaneously, i.e. those arising from situations like a fire, the presence of moisture, overheating, or pests entering the building. By using well-designed products from Super Cable Tray Pvt. Ltd., companies will be able to implement safer, more hygienic, and more dependable cable management, which is in line with the requirements of modern infrastructure and the objectives of durable performance.