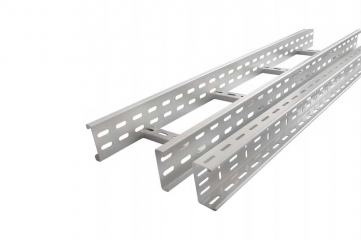

In tough industrial settings, a Galvanized Cable Tray is one of the instruments that ensure the future cable safety, structural integrity, and uninterrupted operations possible. As industry goes for the trend of higher power loads, automation, and harsher operating conditions in 2025, the demand for corrosion, resistant and mechanically strong cable management systems has skyrocketed. The galvanizing thus provides the two protective layers to these trays which makes them the most indispensable facilities safety, durability, and life-cycle value ones.

Dual-layered Protection in Heavy-Duty Industry

Dual-layered protection means the support of a physical barrier that is augmented by sacrificial protection provided by the zinc coating that is applied to the steel during the galvanization process. Steel tray is protected even if it is constantly exposed to moisture, chemicals, or abrasive environment types, this method is far from conventional surface coatings. This double guard system is a guarantee for the uninterrupted execution of the task both in indoor and outdoor areas where long, term reliability is not a subject of negotiation.

Physical Barrier Protection

The external zinc layer is a tightly woven, unbroken blanket that separates the steel back from the outer world. This shell takes the metal off the hook from water, oxygen, and aggressive agents, the usual culprits of rust, by not letting them get direct access. In places of heavy industrial pollution and thus continuous exposure, this film is the main factor in slowing down the destruction of the material and consequently, the maintaining of the tray's strength capacity for a longer period of time.

Some of the most important physical barrier protection advantages are:

- The risk of surface corrosion is lowered in a humid environment or one that is prone to chemicals

- Resistance to abrasion is improved during cable installation and maintenance

- Structural integrity remains at a high level throughout long operational lifecycles

Sacrificial Protection

In addition to its role of a barrier, zinc can also give sacrificial or cathodic protection. In the case of a scratch or a cut, the zinc near the injured site corrodes first thereby protecting the steel that is exposed. The self-healing action of the metal stops the development of rust in the area and so the main strength of the tray is kept even though it has suffered some physical damage.

Reasons why sacrificial protection is necessary for industries:

- It prevents corrosion from going under the coating

- It makes by and large the preemption of frequent touch, up maintenance possible

- It is a means of keeping trust in safety levels even in the case of high-impact installations

Longevity and Cost Efficiency for Industrial Operations

Industrial facilities are commonly running their operations 24 hours a day, 7 days a week. Hence, shutdowns for infrastructure repairs are both costly and disruptive. Through dual-layered protection, the service life of cable trays is practically extended to several decades and so, the maintenance is kept to the minimum. Such a lifespan decreases the intervals between replacements and the total cost of ownership goes down as well, thus, galvanization turns out to be a financially strategic choice for long-term projects.

Safety Assurance in High-Risk Environments

Corrosion, related failures decrease the level of safety of cable support systems which in turn, may cause the systems to sag, the insulation to be damaged, and the risk of fire to increase. Dual-layered protection guarantees that the tray will still be structurally strong under the weight of the heavy cable loads and hence, it will be able to ensure the safety of the operations in the oil and gas industry, power generation, and heavy manufacturing, among others. The use of safe and reliable cable support is one of the factors which directly leads to the observance of strict industrial safety regulations.

Performance in Harsh and Coastal Conditions

Facilities situated close to the sea or areas where chemicals are being processed are very susceptible to corrosion due to air saturated with salt and gases that are highly reactive. Galvanized trays are very good in such surroundings as they are able to resist fast disintegration of the material. Their feature of being able to endure continuous exposure makes them a preferred choice to be used in infrastructure projects where there is a need for performance to be maintained at extreme conditions for a long time.

Versatility Across Cable Management Systems

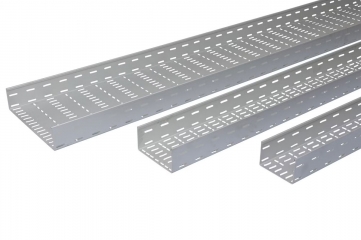

Present-day industrial setting layouts, in most cases, use various cable routing solutions that are aimed at the efficient management of power, data, and communication networks. In such situations, systems such as Raceway Cable Tray solutions work well with galvanized trays in that they make it possible to have a well-organized distribution of different architectural layouts. The said adaptability guarantees that there is a smooth integration into complicated electrical frameworks without the protection standards being weakened.

Trusted Manufacturing and Engineering Excellence

Super Cable Tray Pvt. Ltd. delivers engineered cable management solutions that combine advanced galvanization techniques with precise fabrication standards, by integrating Perforated Cable Trays. Within its diversified product range, the company addresses ventilation, load management, and corrosion resistance in a single solution-supporting industries that demand reliability and long-term value. This commitment to engineering excellence positions the brand as a dependable partner for large-scale industrial and infrastructure projects.

Supporting Scalable and Future-Ready Installations

As factories change their processes, cable networks are also expanding and changing to newer technologies. The use of dual, layered protection can be one of the factors to make trays to be reliable even when there are more cables or the cable layout is changed. Because of their open and strong structure, upgrading is very easy while the same safety and performance levels are kept, thus these systems can be called future-ready investments.

Conclusion

Dual, layered protection is not only a technical characteristic; it is a strategic benefit for the sectors that are looking for safety, durability, and cost savings. Galvanized systems, through the combination of strong barrier protection and sacrificial defense, provide a high level of resilience where there are difficult conditions. Super Cable Tray Pvt. Ltd. is always there to help the industrial sector to grow by providing the solutions that are in line with the modern safety standards and the long-term operational goals, thus making galvanized cable management not only a wise but also a sustainable choice.