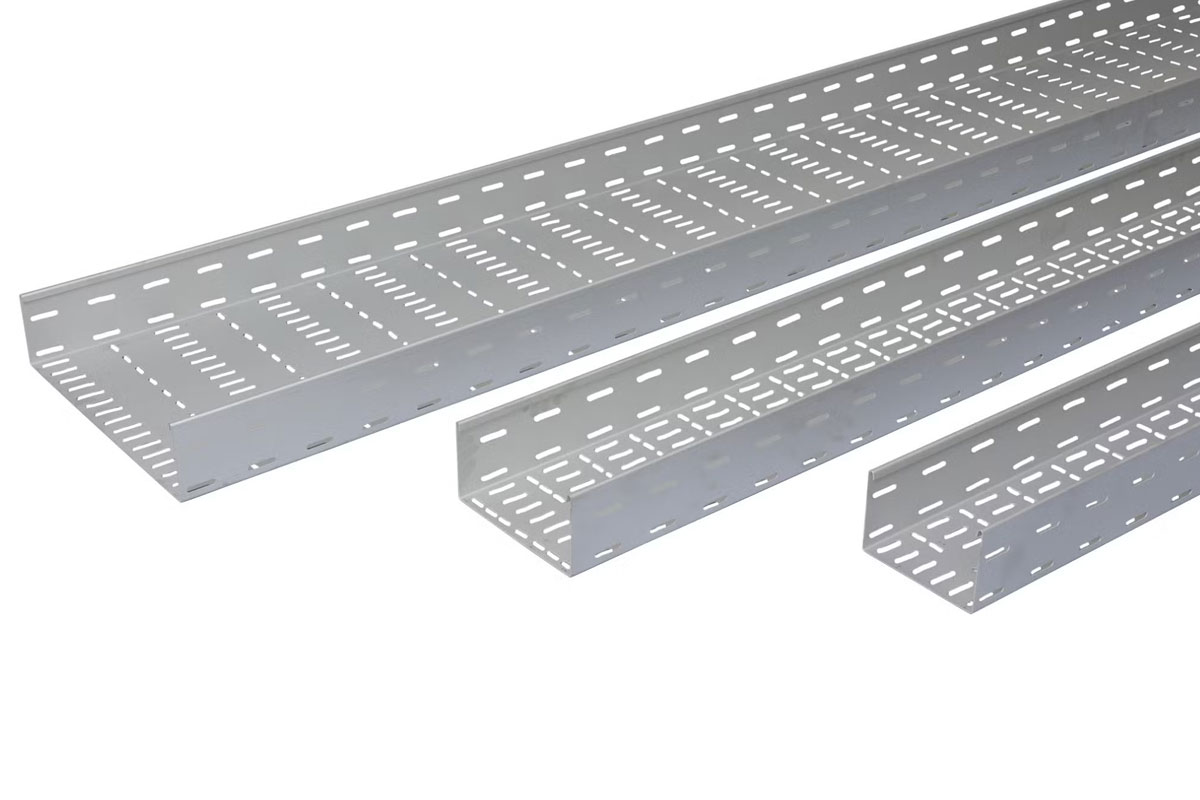

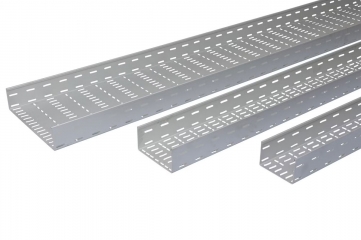

Let's be honest, dealing with messy cables is nobody's idea of a good time. When wires are all over the place and unprotected, you're basically asking for trouble. A Galvanized Cable Tray from Super Cable Tray Pvt. Ltd. gives you a solid way to keep everything neat and safe. The zinc coating on these trays is like armor against rust and environmental damage. They create clear pathways so your cables don't end up looking like tangled spaghetti. Whether you're managing a shopping mall or a factory, getting your cables organized properly just makes sense.

Rust Protection That Actually Works for Years

Here's the thing about metal: it rusts, especially when moisture or chemicals are around. The zinc coating on these trays acts like a shield protecting the steel underneath. It's not just painted on; it actually bonds with the metal at a molecular level. If you've got high humidity or chemical fumes in your facility, this coating is a lifesaver. You won't see those ugly rust spots popping up after just a couple of years. The zinc literally takes the hit before the base metal gets damaged. We're talking about cable infrastructure that stays solid for decades, not something you'll replace in five years.

Keeps Fire Hazards Under Control

Nobody wants to think about fires, but when you're working with electrical systems, it's important. These metal systems won't catch fire or help spread flames; that's a huge deal. The zinc coating doesn't release nasty toxic fumes when things get hot, either. If you do have an electrical fault or overheating issue, the metal structure helps contain it. Building inspectors often require non-combustible materials in certain areas, and these systems check that box. Having fire-safe infrastructure also tends to keep your insurance company happy. It's one of those things that hopefully never matters, but you're glad it's there.

Makes Life So Much Easier When Things Go Wrong

Ever tried finding one specific cable in a giant tangled mess? It's maddening, right? Organized cable pathways save your maintenance crew tons of frustration and time. A Gi Perforated Cable Tray gives you the same organizational benefits plus better airflow. When your team can work efficiently, everybody wins. Here's why it matters:

- Find Problems Fast: When everything's organized, tracking down a faulty cable is actually manageable

- Get Back Online Quickly: Less time troubleshooting means less downtime for your operations

- Safer for Workers: Nobody's stumbling over loose cables or squeezing into dangerous spaces

- Easy to Label: You can clearly mark what goes where for future reference

Shields Your Cables From Everyday Damage

Think about how much stuff happens in a typical facility—forklifts moving around, equipment being installed, things getting bumped. The solid metal structure protects your cables from all that chaos. Workers won't accidentally crush cables when they're moving materials or machinery around. Keeping cables elevated means they're safe from floor hazards like water leaks or spills. You eliminate those sharp bends and stress points that slowly kill cables over time. This protection means your cables last way longer and you're not constantly replacing them. You're basically building a protective highway for all your electrical connections.

Stops Cables From Sagging and Breaking Down

When cables aren't supported properly, they start to sag and develop weak spots that eventually fail. Ladder Cable Trays excel at load distribution with their sturdy open framework design. When cables are properly supported, they work better and survive much longer than stressed ones. These systems spread the weight evenly so no single point takes all the stress. The solid structure keeps cables from drooping, which can damage their outer jackets or internal wires. Here's what proper support does for you:

- Keeps Cables Healthy: Support prevents bending them past their breaking point

- No Weak Spots: Weight gets distributed instead of creating points that'll fail first

- Room to Grow: You can add more cables later without overloading the system

- Fewer Emergency Calls: Less stress on cables means fewer middle-of-the-night failures.

Final Thoughts

Building a safe and organized electrical setup isn't just about checking boxes on compliance forms. It's really about creating systems that protect what you've invested in and make everything run smoother. The right approach to managing cables stops problems before they even start while making maintenance way less painful. From keeping rust away to minimizing fire risks, quality systems pay dividends that add up over the years. As buildings and facilities get more complex with new tech and equipment, having rock-solid infrastructure becomes absolutely crucial. Spending money on proper cable management now saves you from expensive disasters down the road.