Types of Cable Trays: Benefits and Uses

In modern electrical and industrial infrastructure, managing cables safely and efficiently is just as important as selecting the right cables themselves. Poor cable organization can lead to overheating, signal interference, maintenance difficulties, and even fire hazards. This is where a Cable Tray system becomes essential.

Cable trays provide a structured pathway for routing, protecting, and supporting power, control, and data cables across industrial plants, commercial buildings, data centers, hospitals, and infrastructure projects. Over the years, different types of cable trays have been developed to suit specific load requirements, environments, and installation conditions.

This guide explains the major types of cable trays, their benefits, applications, and how to choose the right system for your project.

What is a Cable Tray System?

A Cable Tray is a rigid structural system designed to support insulated electrical cables and wiring. Instead of running cables through conduits, trays allow easy installation, inspection, ventilation, and future expansion.

Why Cable Trays Are Essential

Using a proper cable tray system offers many advantages:

-

Improved Safety: Reduces fire risks and cable damage

-

Better Ventilation: Prevents overheating

-

Easy Maintenance: Quick cable inspection and replacement

-

Cost-Efficient: Lower installation and labor costs

-

Scalability: Easy to add or remove cables

-

Organized Infrastructure: Cleaner and safer workspaces

Major Types of Cable Trays

Different environments require different tray designs. Below are the most widely used cable tray types.

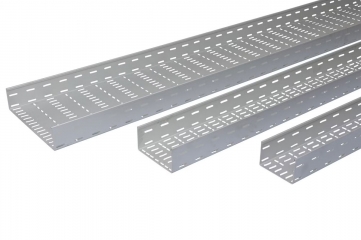

1. Perforated Cable Trays

Perforated Cable Trays feature evenly spaced holes across the tray surface. These perforations allow airflow, drainage, and easy cable tying.

Benefits

Applications

-

Commercial buildings

-

Data centers

-

Control panels

-

Power distribution rooms

2. GI Perforated Cable Tray

A GI Perforated Cable Tray is manufactured from galvanized iron steel with a zinc coating that protects against corrosion and rust.

Benefits

Applications

-

Industrial factories

-

Warehouses

-

Power stations

-

Chemical plants

3. Raceway Cable Tray

A Raceway Cable Tray is a fully enclosed or partially enclosed system designed to provide maximum protection to cables.

Benefits

-

Protects cables from dust, moisture, and physical damage

-

Provides a neat and concealed appearance

-

Enhances workplace safety

Applications

-

Office buildings

-

Hospitals

-

Laboratories

-

Airports and malls

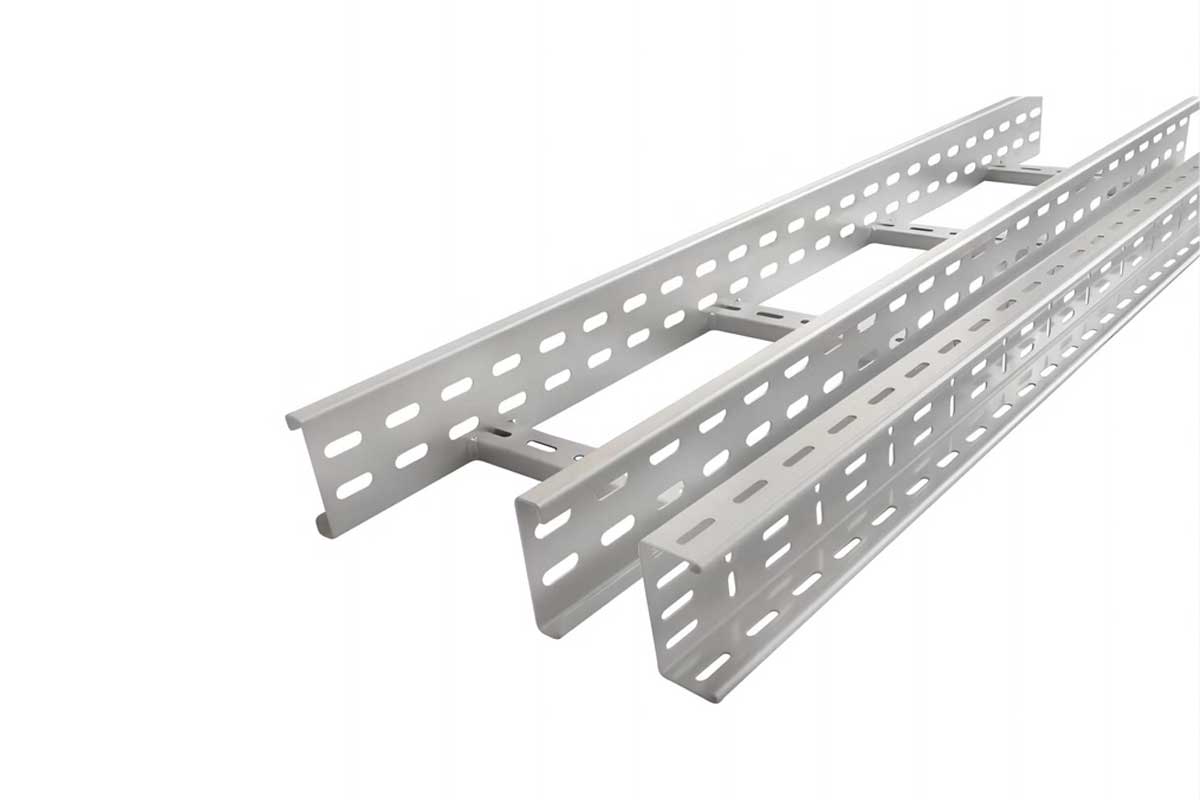

4. Ladder Cable Trays

Ladder Cable Trays have a ladder-like structure with two side rails and rungs.

Benefits

-

Excellent airflow for heat dissipation

-

Suitable for heavy cables

-

Easy cable entry and exit

-

High load capacity

Applications

5. Galvanized Cable Tray

A Galvanized Cable Tray is coated with zinc through hot-dip or pre-galvanization to resist corrosion.

Benefits

-

Superior corrosion protection

-

Durable for harsh environments

-

Cost-effective long-term solution

Applications

-

Outdoor installations

-

Coastal areas

-

Industrial environments

-

Renewable energy plants

Comparison Table: Types of Cable Trays

| Type |

Strength |

Corrosion Resistance |

Ventilation |

Best For |

| Perforated Cable Trays |

Medium |

Medium |

High |

Commercial & control systems |

| GI Perforated Cable Tray |

High |

High |

High |

Industrial environments |

| Raceway Cable Tray |

Medium |

High |

Low |

Offices & sensitive areas |

| Ladder Cable Trays |

Very High |

Medium |

Very High |

Heavy industrial power cables |

| Galvanized Cable Tray |

High |

Very High |

Medium |

Outdoor & corrosive areas |

How to Choose the Right Cable Tray

When selecting a cable tray system, consider:

-

Load Capacity – number and weight of cables

-

Environmental Conditions – moisture, heat, chemicals

-

Installation Area – indoor or outdoor

-

Ventilation Needs – high heat environments need airflow

-

Safety Standards – fire and electrical regulations

-

Future Expansion – ease of upgrades

Industry Standards & Compliance

High-quality cable trays comply with:

-

IS standards

-

NEMA VE-1

-

IEC guidelines

Certified manufacturing ensures safety, durability, and regulatory compliance.

Conclusion

Choosing the right Cable Tray system is not just about cable support—it’s about ensuring safety, efficiency, and long-term performance. From Perforated Cable Trays and GI Perforated Cable Trays to Raceway Cable Tray, Ladder Cable Trays, and Galvanized Cable Tray, each type serves a unique purpose across industries.

By understanding their benefits and applications, you can design a reliable cable management system that improves workflow, reduces risks, and supports future growth.

A well-planned cable tray solution is a long-term investment in safety, performance, and infrastructure reliability.