In today’s industrial and commercial electrical systems, proper cable management is not optional—it is essential. Poorly routed cables can lead to safety hazards, power failures, difficult maintenance, and higher operational costs. A raceway cable tray is a reliable and widely accepted solution that helps organize, protect, and support electrical and communication cables in a structured way.

Raceway cable tray systems are designed to provide enclosed or semi-enclosed protection, making them suitable for environments where cables need shielding from dust, moisture, mechanical damage, and accidental contact. Because of their durability, flexibility, and ease of maintenance, raceway cable trays are used across industries worldwide.

What Is a Raceway Cable Tray?

A raceway cable tray is an enclosed electrical raceway system used to route power cables, control cables, and data cables safely. Unlike open ladder or perforated trays, raceway systems offer better cable protection by covering the cables from external exposure.

These systems are commonly used in industrial plants, commercial buildings, data centers, power stations, and infrastructure projects where safety, cleanliness, and organized cable routing are critical. Raceway cable trays also allow easier inspection and future cable additions compared to rigid conduit systems.

Types of Raceway Cable Tray Systems

Different applications require different raceway designs. The most common types include:

Solid Bottom Raceway Cable Tray

This type provides complete cable protection and is ideal for power, control, and instrumentation cables. It is commonly used where environmental protection and safety are top priorities.

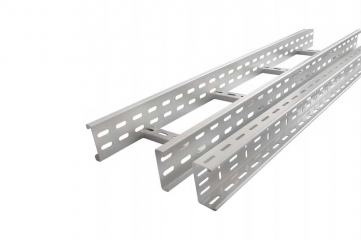

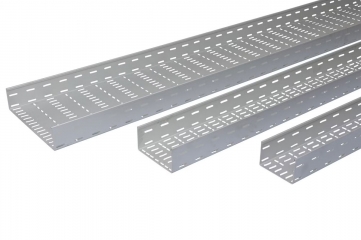

Perforated Raceway Cable Tray

Perforated raceway trays include ventilation holes that allow airflow and heat dissipation. They are suitable for power cables and installations where heat buildup must be controlled.

Wire Mesh Raceway Cable Tray

Wire mesh raceway trays are lightweight and flexible. They are mainly used for data, telecom, and low-load applications where quick installation and easy cable modification are required.

Raceway Cable Tray Sizes

Choosing the correct size is essential for safe operation and future expansion. Raceway cable tray sizes depend on cable quantity, cable diameter, and load requirements.

| Width (mm) |

Depth (mm) |

Typical Application |

| 50 – 100 |

50 |

Data and control cables |

| 150 – 300 |

75 – 100 |

Industrial power cables |

| 450 – 600 |

100 – 150 |

Heavy-duty installations |

Manufacturers often provide custom sizes to match specific project requirements.

Raceway Cable Tray Materials & Specifications

Material selection plays a major role in performance and durability. Raceway cable trays are typically manufactured from mild steel, galvanized iron, aluminum, and stainless steel. Key specifications include tray thickness, load-carrying capacity, surface finish, corrosion resistance, and compliance with electrical standards.

MS Hot Dip Galvanised Raceway

An MS Hot Dip Galvanised Raceway is made from mild steel and coated using the hot-dip galvanizing process. This coating offers excellent corrosion resistance, making it suitable for outdoor installations, chemical plants, coastal areas, and humid environments. These raceways are strong, long-lasting, and require minimal maintenance, making them ideal for heavy industrial use.

MS Powder Coated Raceway

An MS Powder Coated Raceway is mainly used for indoor applications. The powder coating provides a smooth, uniform finish and additional protection against wear and mild corrosion. These raceways are commonly used in commercial buildings, control panels, and electrical rooms where appearance and cleanliness are important.

GI Raceway

A GI Raceway is manufactured from galvanized iron and is one of the most widely used options in industrial and commercial projects. GI raceways offer a good balance of strength, corrosion resistance, and cost efficiency. They are suitable for general electrical installations and indoor environments.

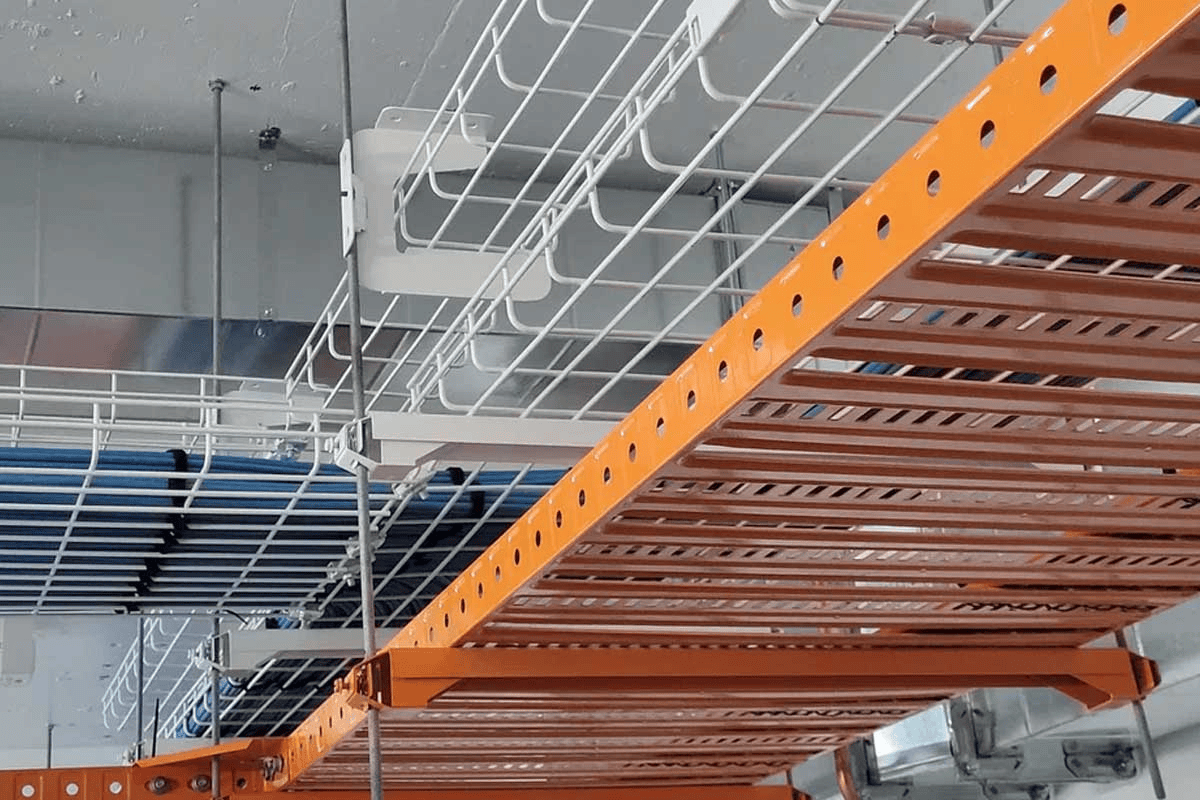

Raceway Cable Tray Installation

Proper installation is critical for safety and long-term reliability. Raceway cable tray installation includes correct support spacing, secure mounting, grounding, and proper alignment. One of the key advantages of raceway systems is easy access for inspection, maintenance, and cable replacement without disturbing the entire system.

Raceway Cable Tray Floor Applications

A raceway cable tray floor system is used when overhead cable routing is not possible. These systems are installed under raised floors in data centers, control rooms, and office spaces. Floor raceways protect cables from physical damage while keeping workspaces clean and hazard-free.

Raceway Cable Tray Price

The raceway cable tray price depends on several factors, including material type, tray size, thickness, surface finish, and order quantity. While the initial cost may vary, raceway cable trays offer long-term value due to durability, easy maintenance, and flexibility for future expansion.

Raceway Cable Tray vs Conduit Systems

Compared to traditional conduit systems, raceway cable trays provide faster installation, better heat dissipation, and easier cable modification. This makes them a preferred choice for modern industrial electrical infrastructure where system upgrades are frequent.

FAQs – Raceway Cable Tray

What is a raceway cable tray used for?

It is used to safely route and protect electrical and communication cables in industrial and commercial installations.

Which material is best for raceway cable trays?

MS hot dip galvanised raceways are ideal for harsh environments, while GI and powder coated raceways are suitable for indoor use.

Can raceway cable trays be installed on floors?

Yes, raceway cable trays are widely used in underfloor and raised floor cable management systems.

How do I choose the right raceway cable tray size?

Tray size depends on cable quantity, load requirements, and future expansion needs.

Conclusion

A well-designed raceway cable tray system improves electrical safety, organization, and efficiency. With multiple options such as MS hot dip galvanised raceway, MS powder coated raceway, and GI raceway, these systems provide reliable and scalable cable management solutions for modern industrial and commercial projects.